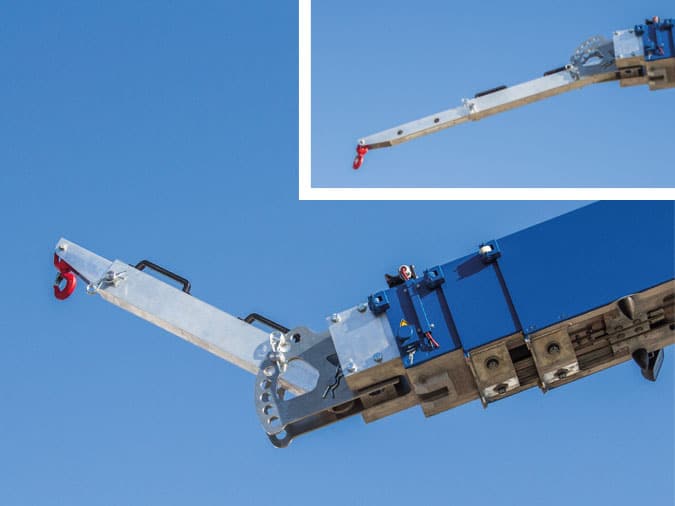

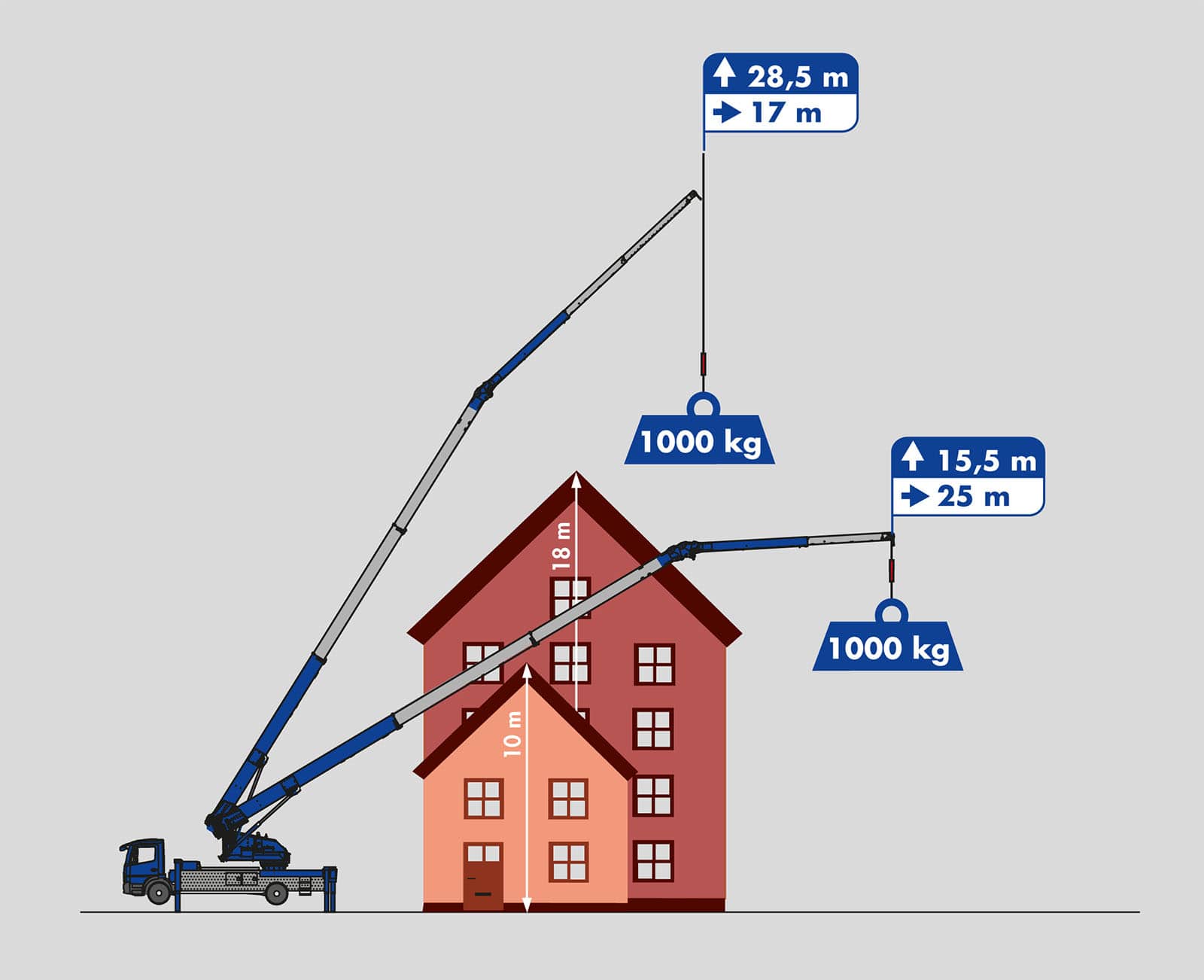

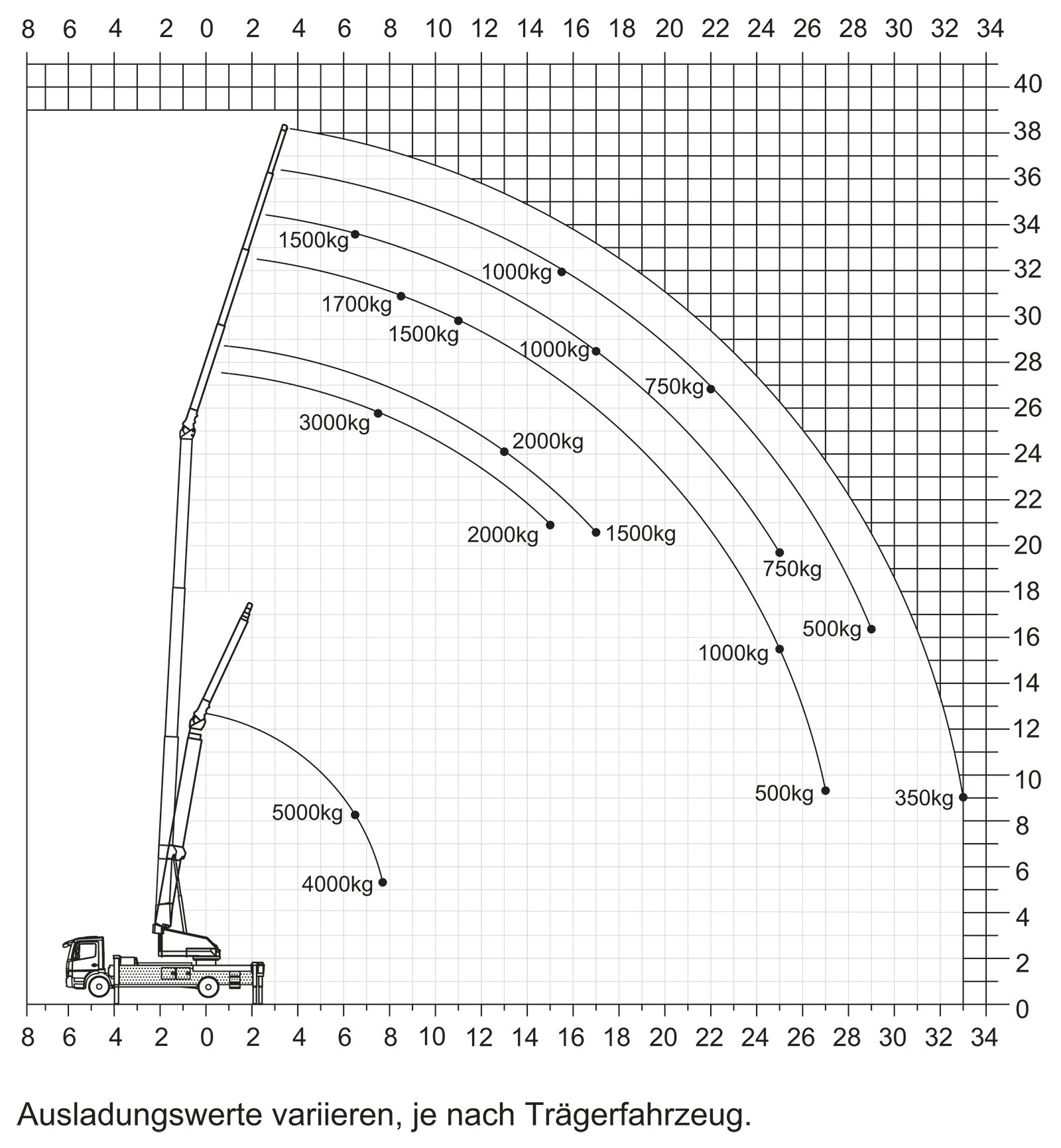

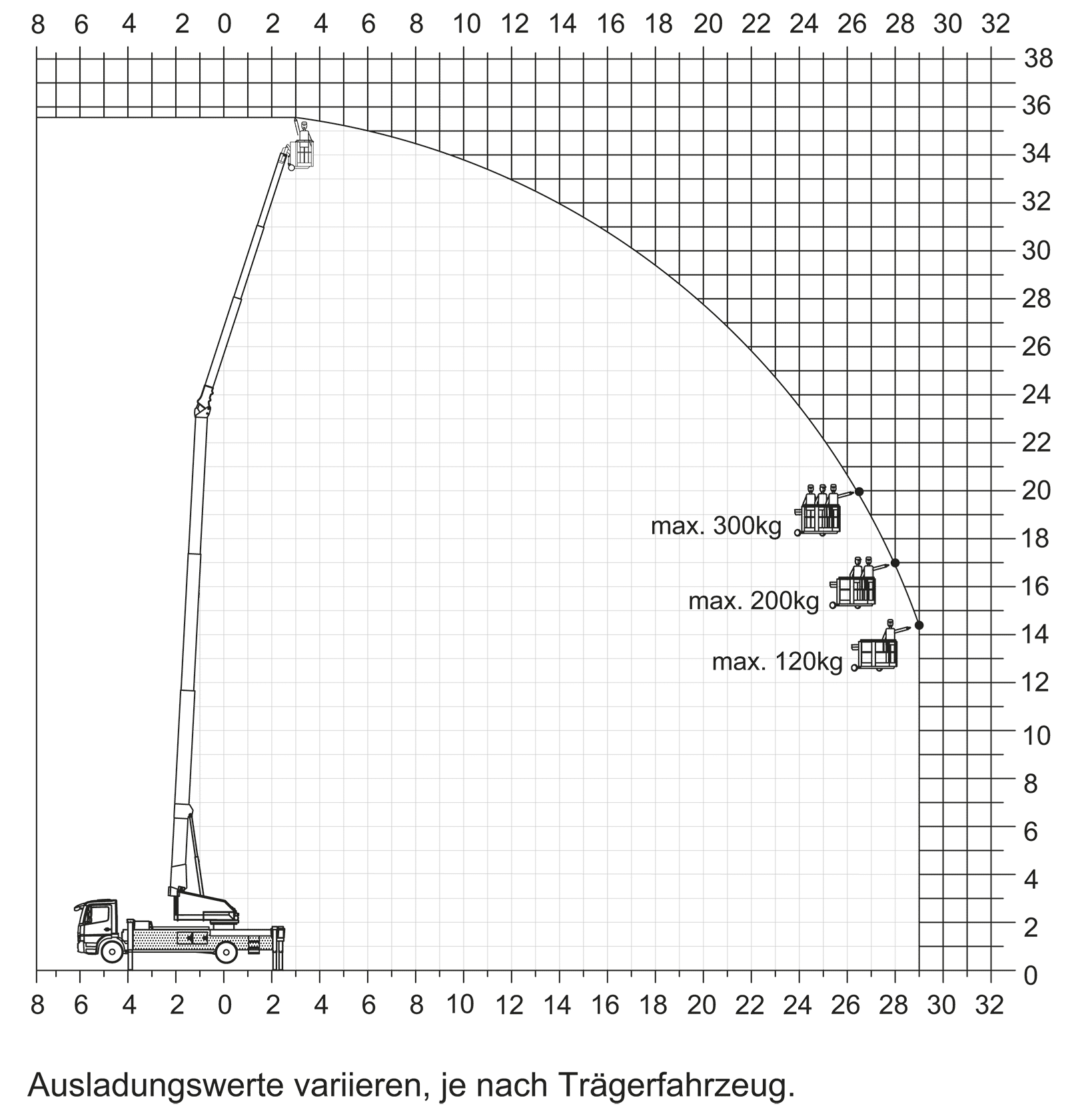

The K900 is impressive due to its hook height of over 38 m as well as due to its enormous strength. With a maximum load capacity of 5,000 kg, it can even reach work areas 6.50 m away and 8.20 m high. Equipped with a double hydraulic telescopic fly jib, the crane can also be set up where there is not much room – also when operating as a work platform.

The all-rounder is equipped with the Klaas comfort package as standard. In addition to the personal security mode and individual programming of the rotation angle, this also includes a memory function. This enables the K900 to recognise two target points and moves between these automatically and in a safe hold-to-run handling mode.