K21-30

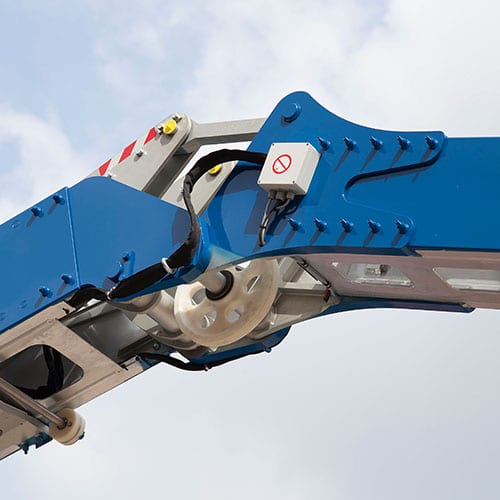

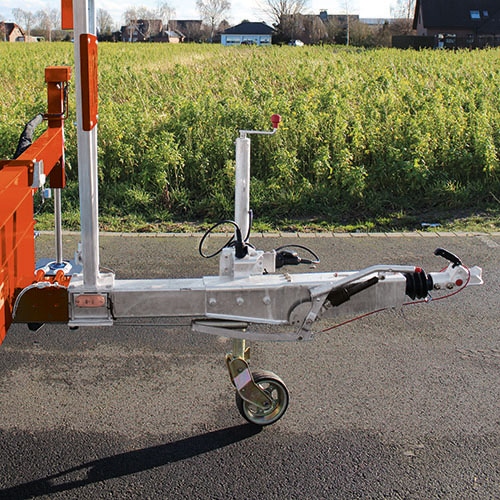

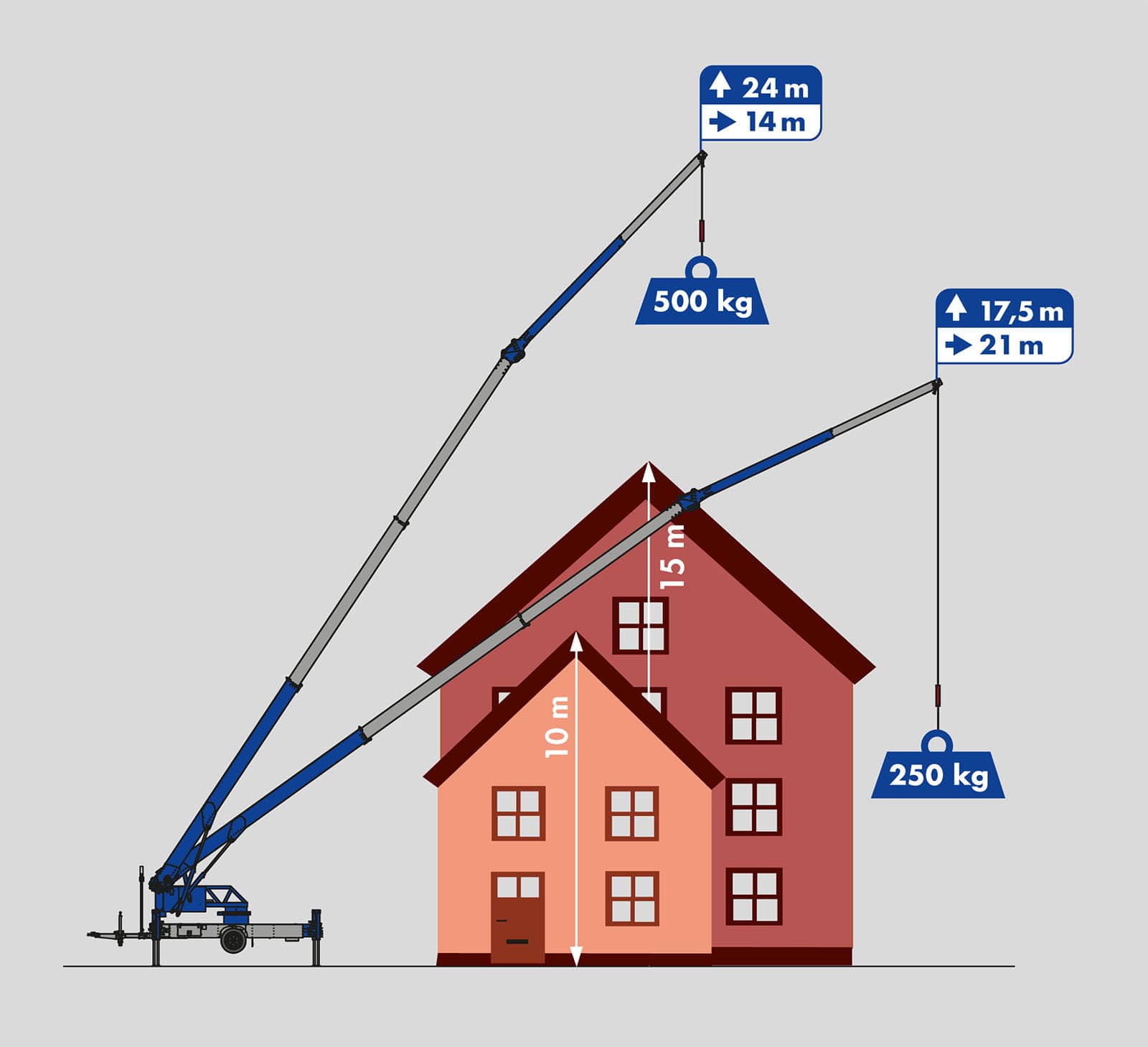

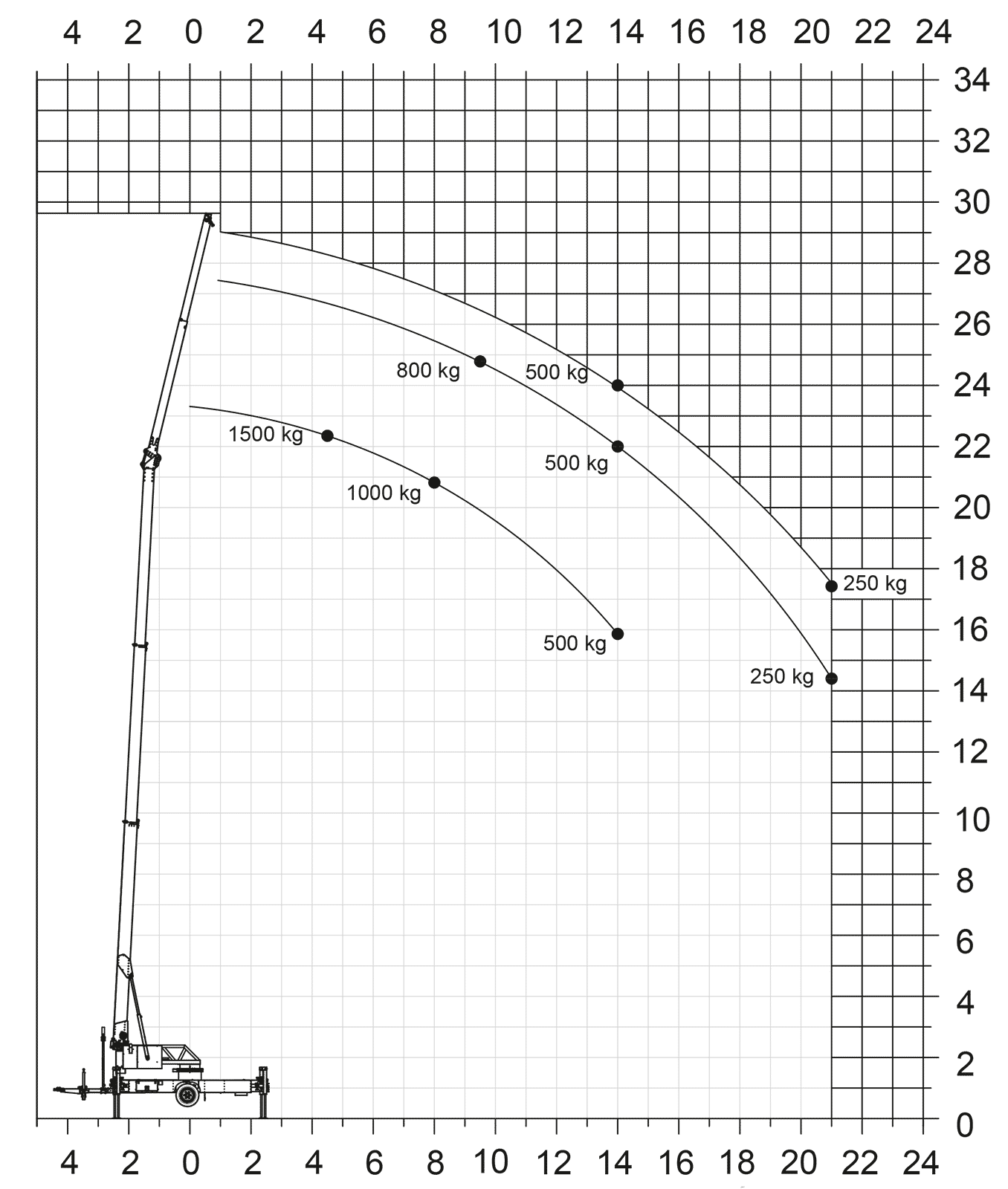

Despite its low net weight of 3.5 t, the K21-30 is an efficient all-rounder. Its tremendously strong fly jib hinge enables loads of up to 1,500 kg to be picked up, whilst it can lift a weight of 250 kg laterally 21 m away. Due to the single-axle operation, the trailer scores highly with great manoeuvrability, optimal weight distribution and more ground clearance. With the help of the self-drive mechanism, the K21-30 can manoeuvre easily on the building site. Thanks to a retractable drawbar, its overall length can be reduced to 7 m, meaning that the crane can also be easily set up in inner-city areas.