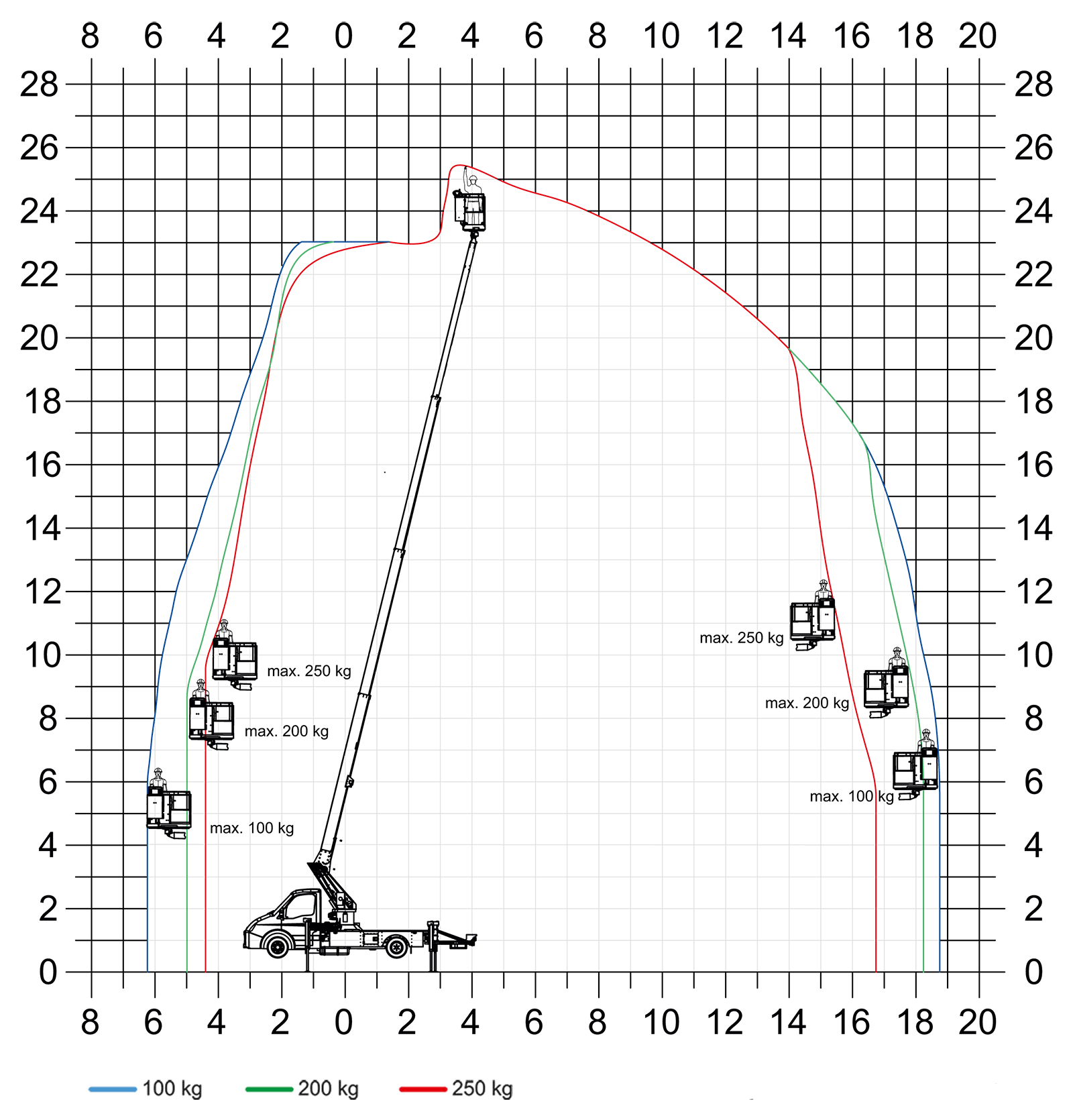

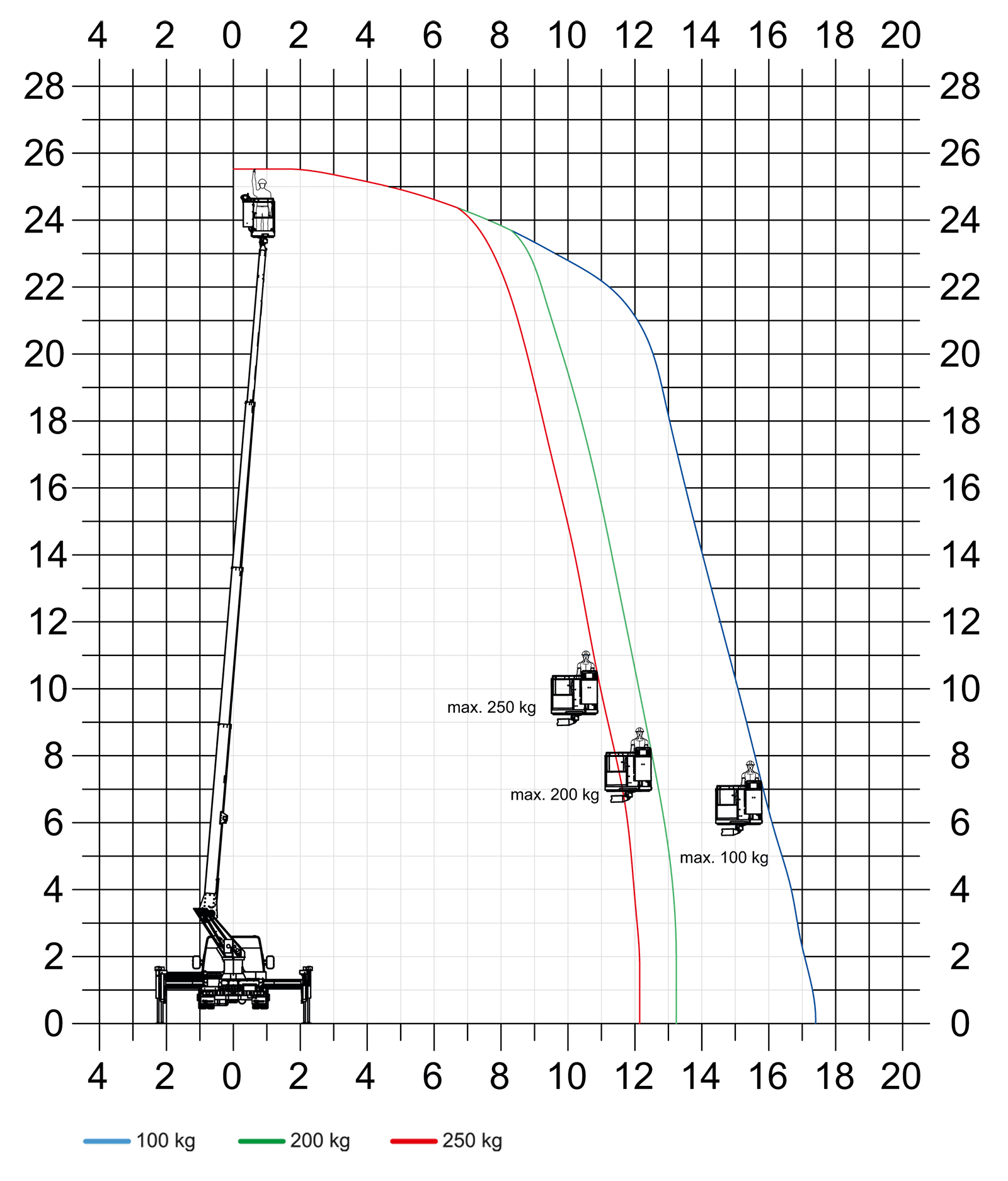

The Theo25 – named after the company founder, Theodor Klaas – with its working height of 25 m plus its enormous reaches to the rear and to the side, not only makes work easier for roofers, building cleaners and assembly firms. The platform can also be used efficiently in a variety of ways for facade engineering and horticultural purposes. Set up on a sturdy Nissan Cabstar, it meets the Euro 6 emissions standard and can thus be used without hesitation in the inner-city area. The ultra-modern CAN BUS control block works extremely sensitively and enables the user to precisely control the platform and reach even difficult to access work areas with pinpoint accuracy.

.