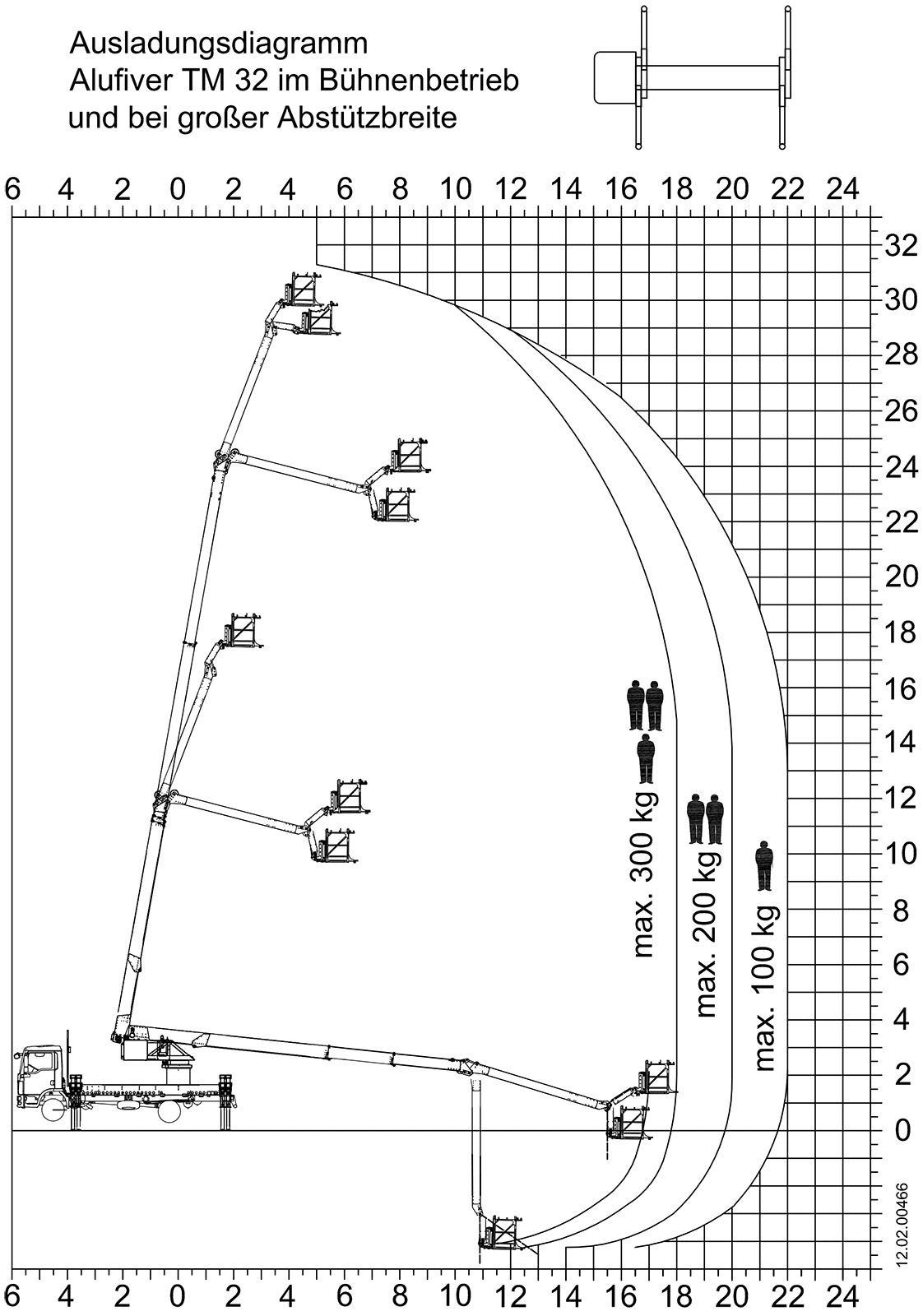

Whether it is used for firefighting or on builder’s yards, this Klaas multifunctional appliance is impressive all round. The ways that the AluFiver can be used are as varied as the cases dealt with every day by the fire brigade and technical support services. It is designed so that firefighters can work quickly and efficiently with the appliance even under extreme conditions. The automatic set-up and dismounting system enables a simple and safe procedure especially in precarious situations. Its compact dimensions make even places that are difficult to reach accessible.