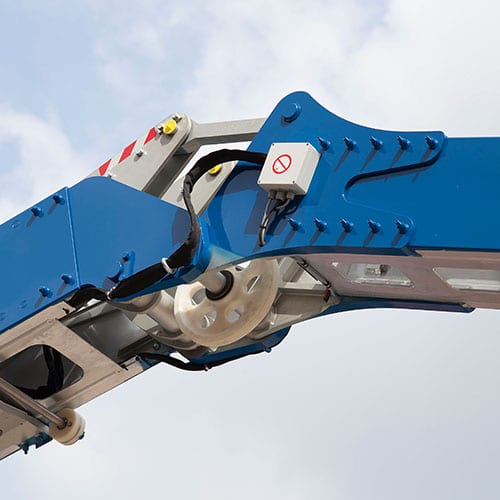

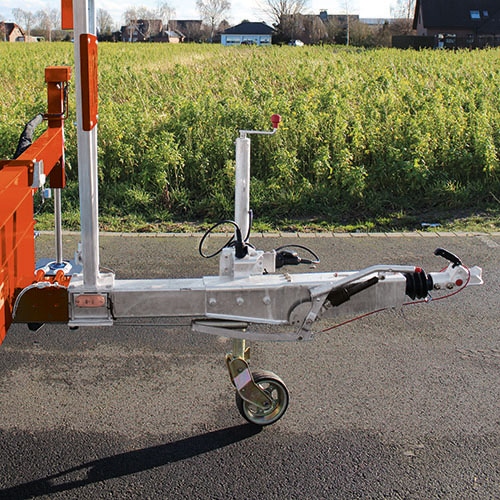

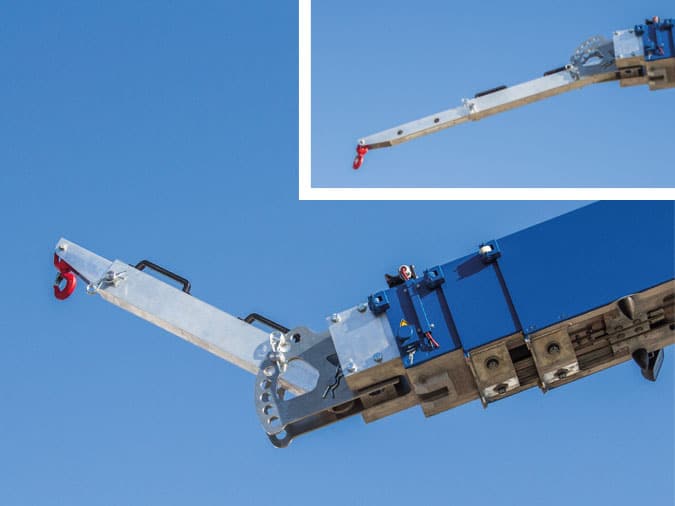

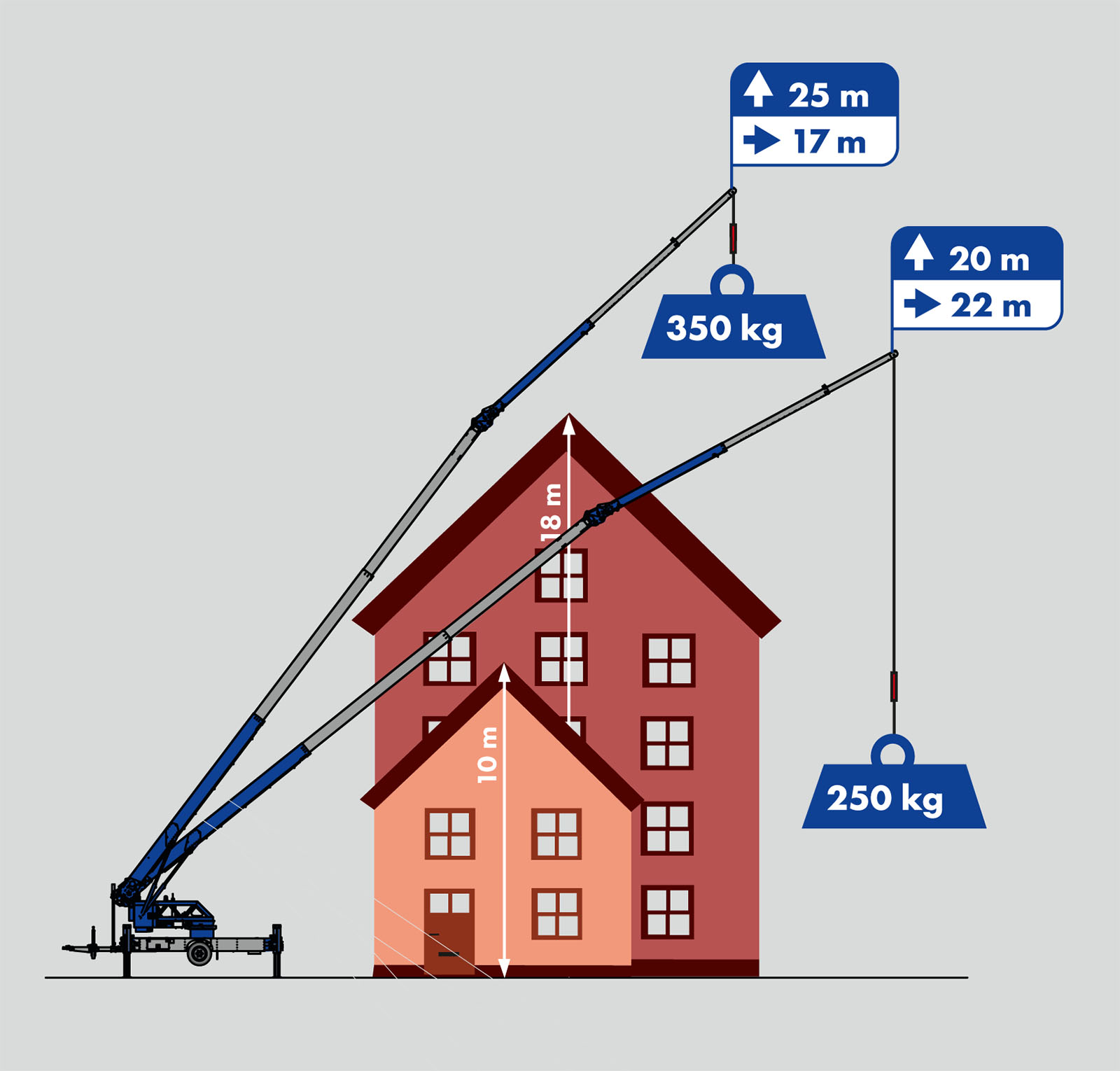

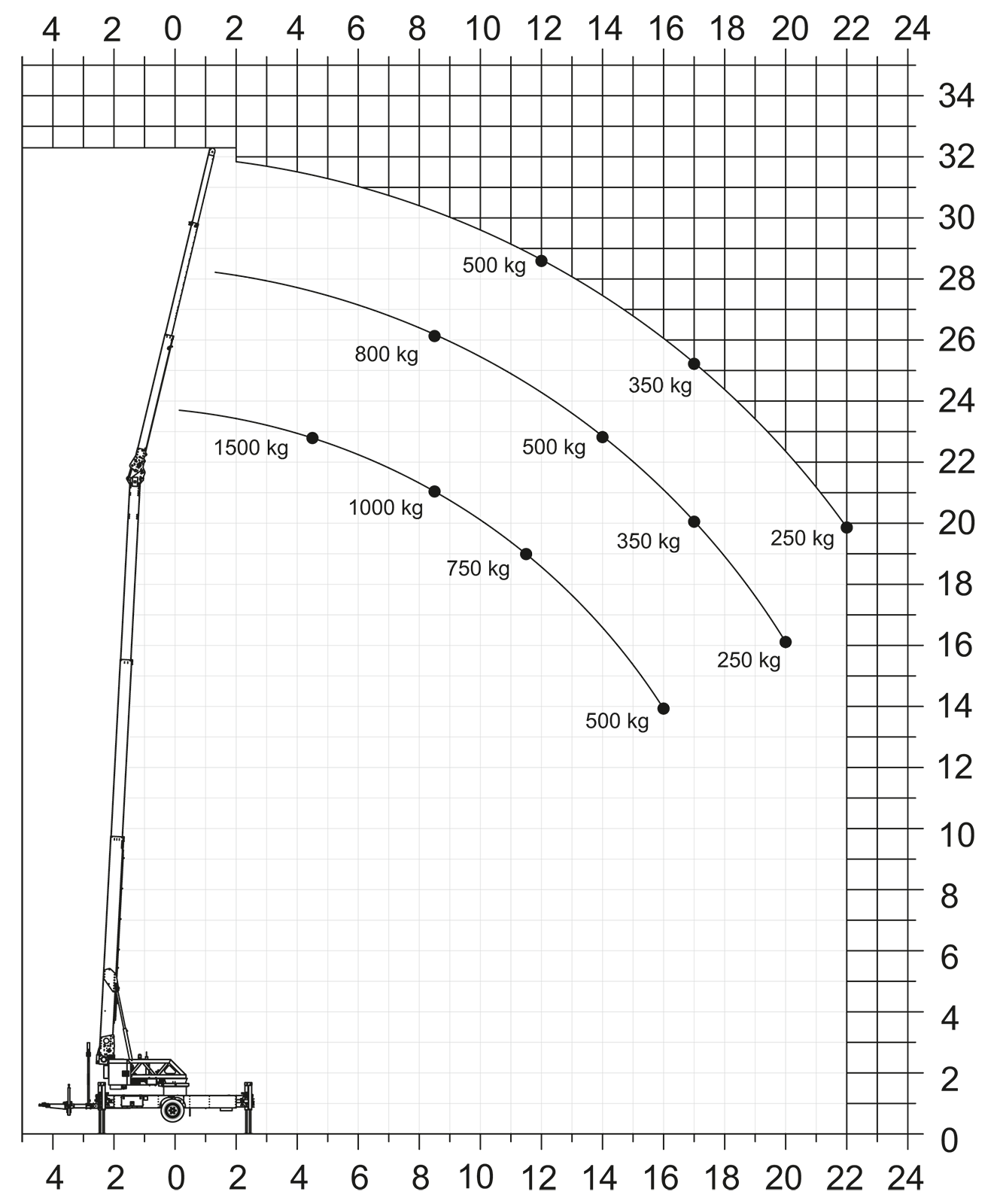

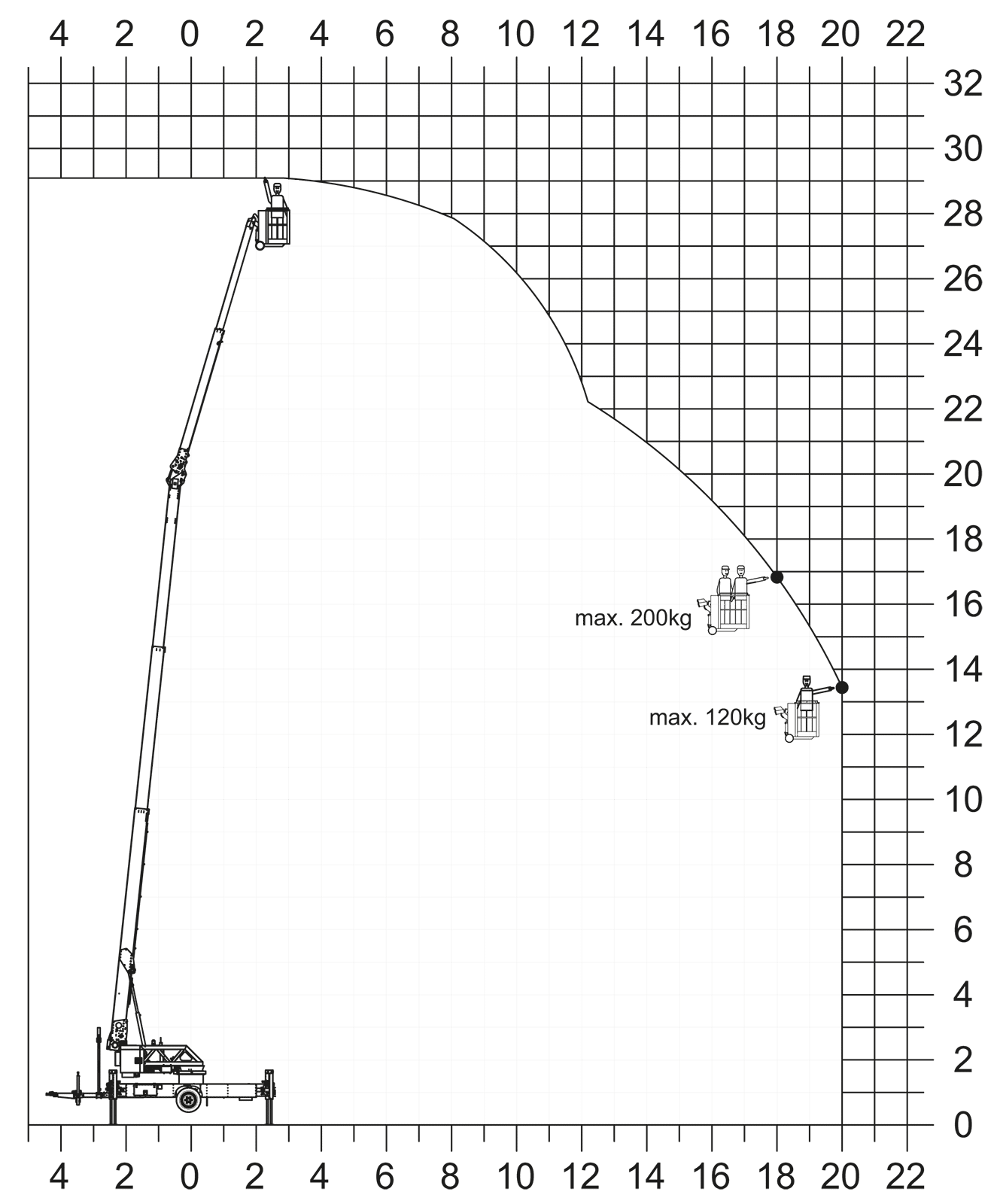

The K350 E is a trailer crane in the 3.5 tonne class with state-of-the-art equipment, high driving comfort and outstanding performance values. Its maximum load capacity is 1,500 kg, the lateral reach with a load of 250 kg is an impressive 22 metres. An absolute Klaas highlight is the hydraulically telescoping folding jib. During platform operation or complex assembly work, the folding jib can be conveniently telescoped in and out by remote control, even under load. This makes complete crane assembly child’s play, even in confined spaces. The battery-powered electric motor, which drives the crane almost silently, is a pioneering feature. The large lithium battery can also be charged at any conventional 230-volt socket during crane operation, although this is rarely necessary as the K350 E can easily be used for an entire working day without recharging. Due to its high performance, the high-quality lithium battery requires only a few charging cycles and is therefore particularly user-friendly and stable in value.