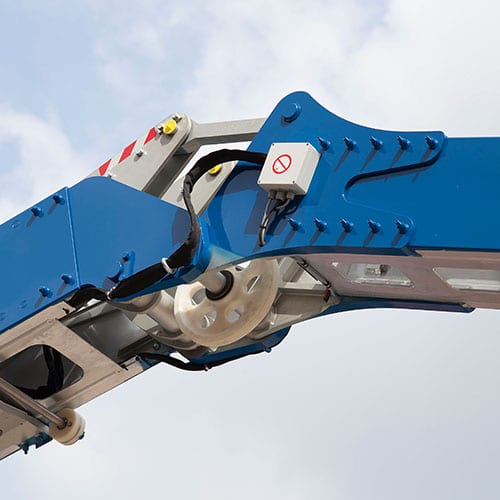

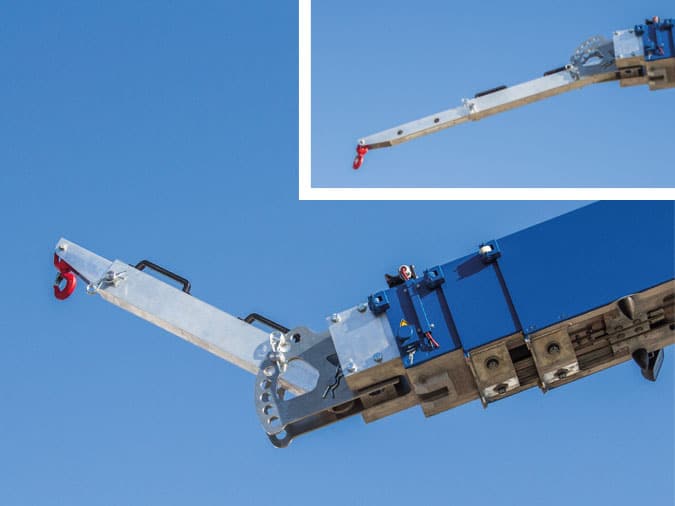

The K760 is equipped with a double hydraulically telescopic folding jib, where the first two elements can be extended over a length of 5.00 to 11.65 m via the radio remote control. This makes the crane set-up and the application possibilities even more comfortable and versatile.

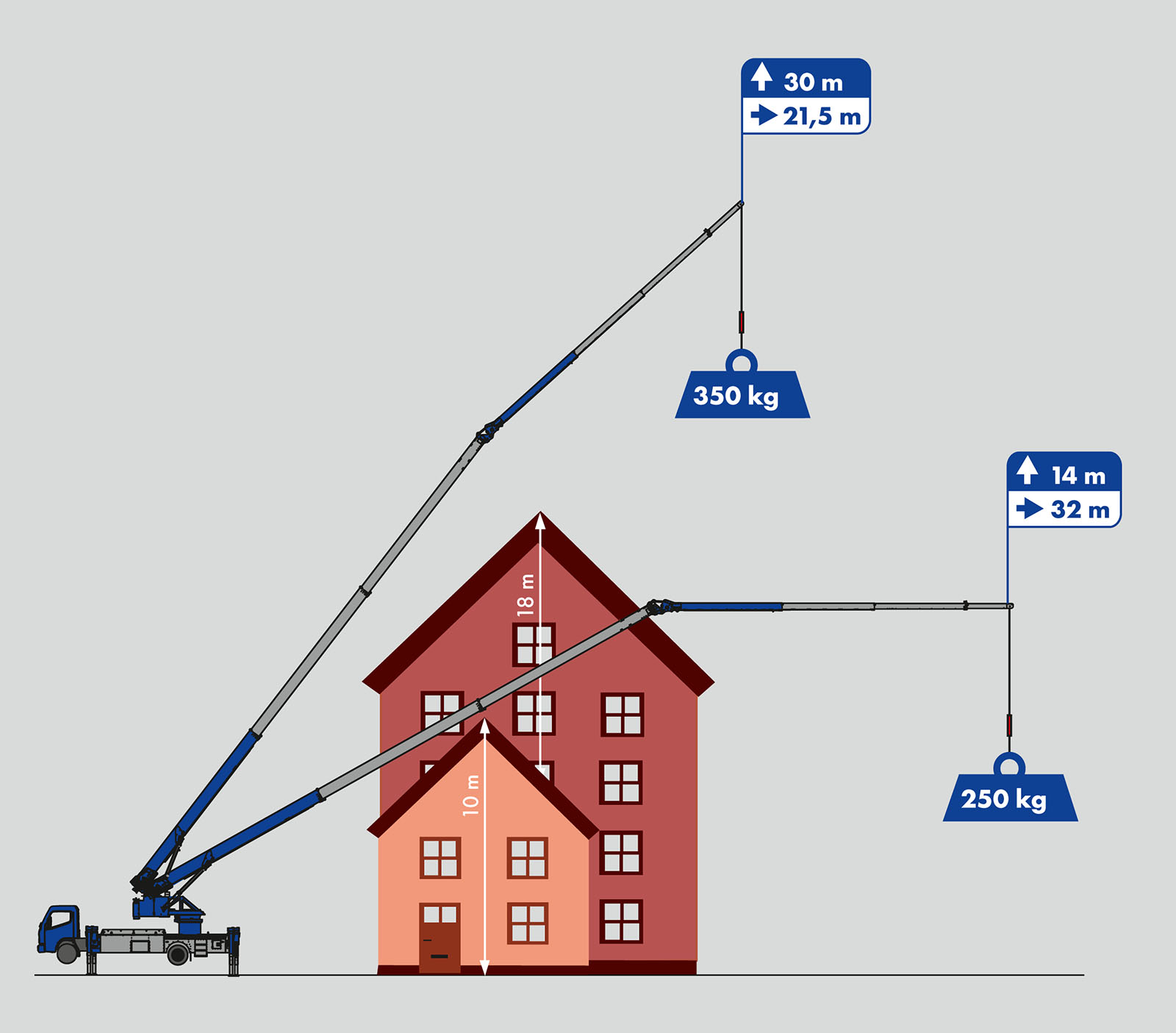

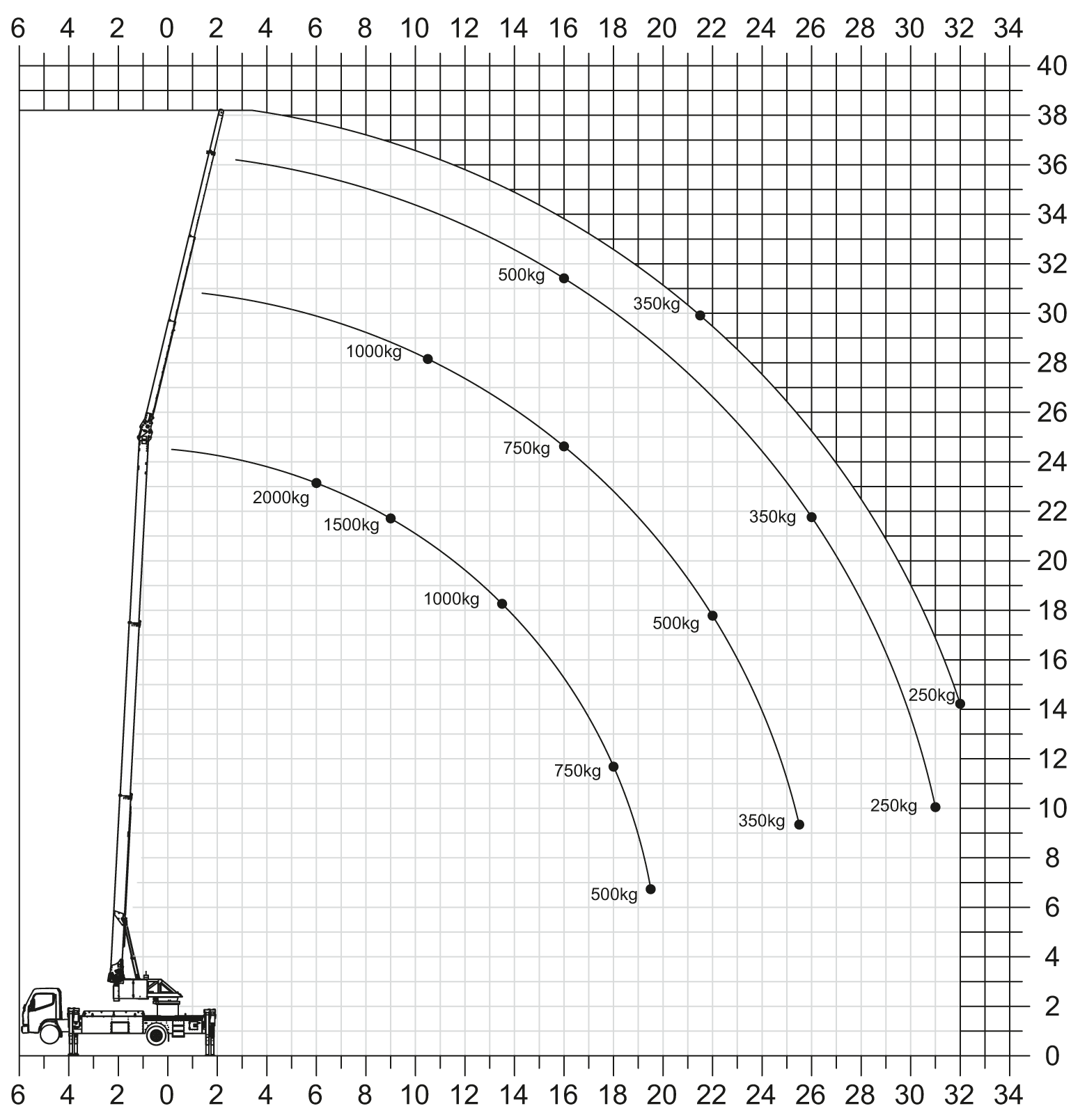

The K760 uses a high-quality, lightweight plastic hoisting rope. This has enabled the performance values to be increased once again and the lifting behaviour to be further improved. With a load of 250 kg, its reach is 32 m, and the all-rounder can lift material weighing up to 500 kg 22 m.