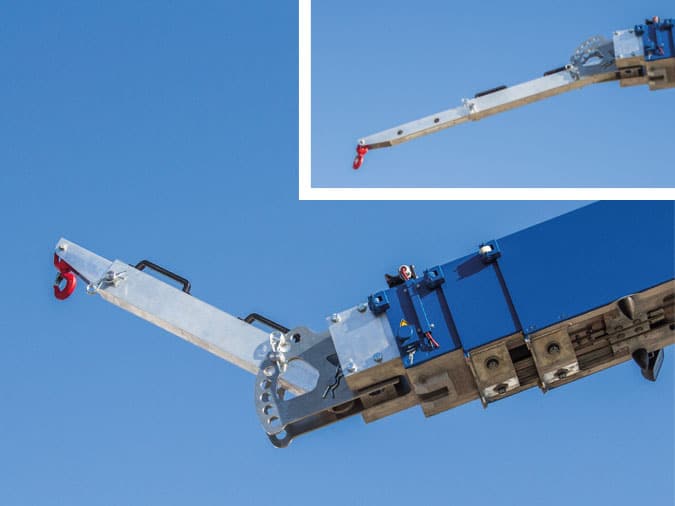

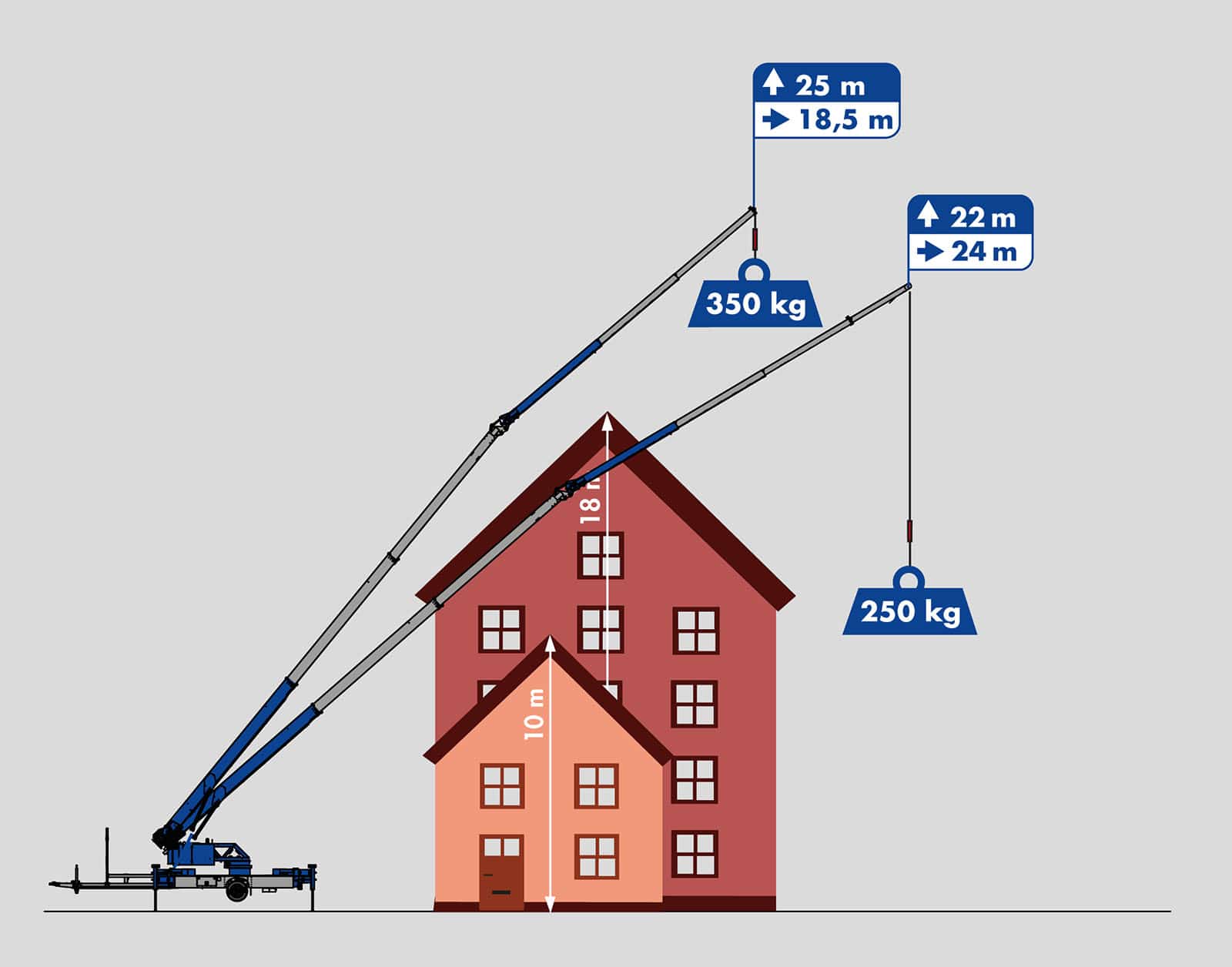

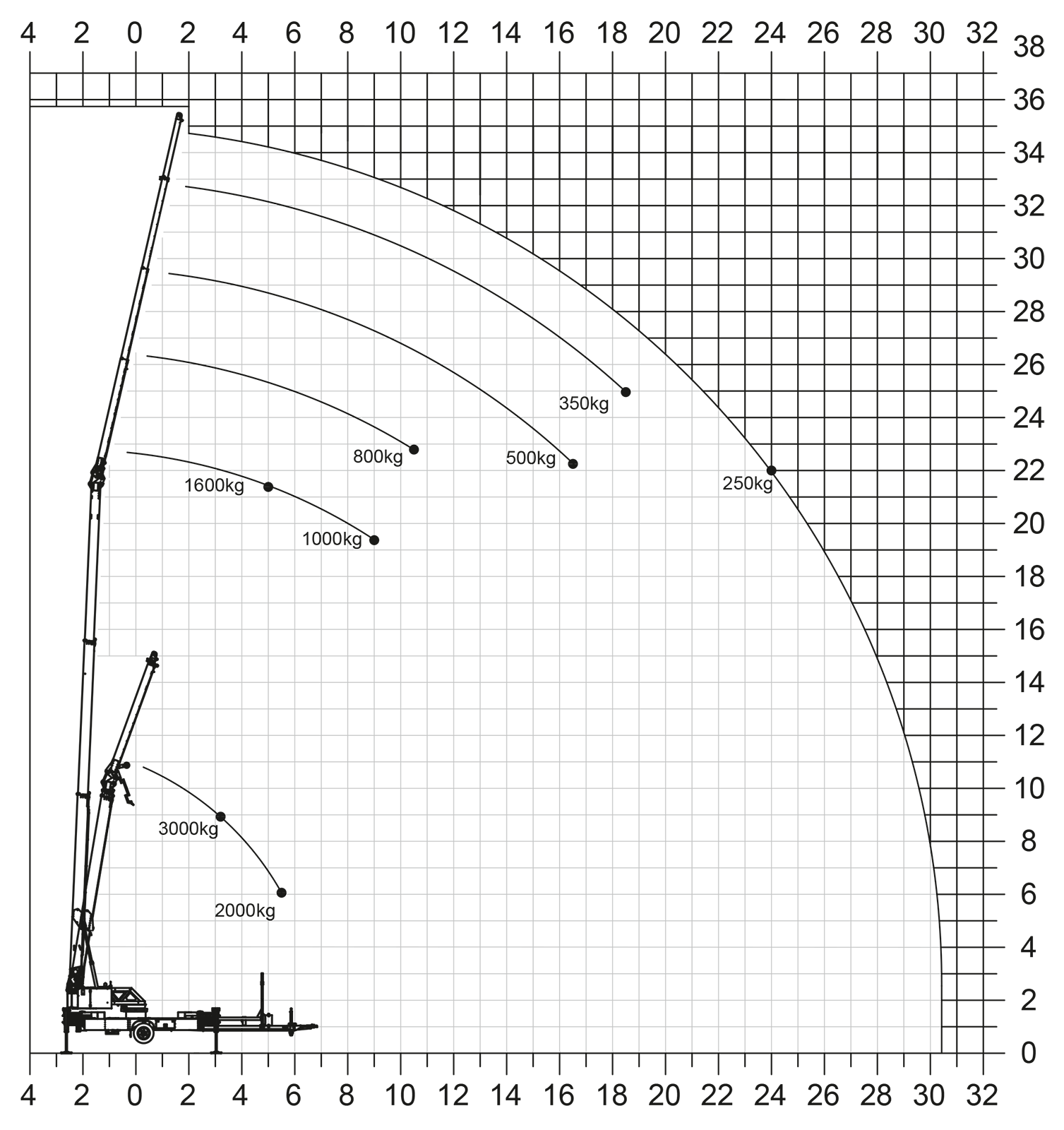

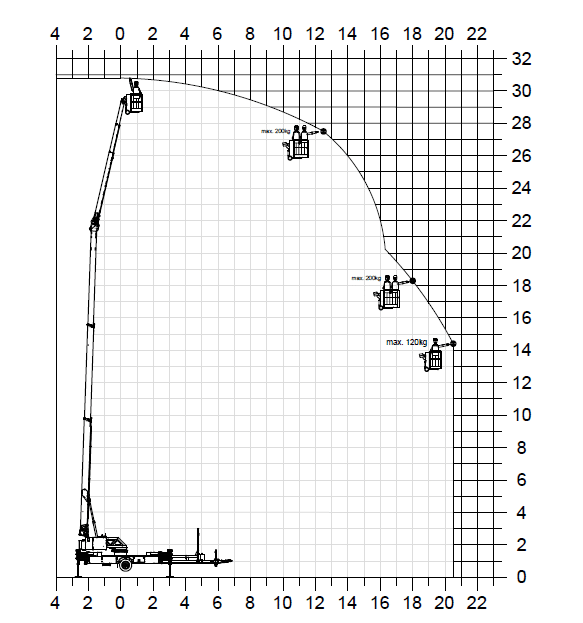

With a maximum load capacity of 3,000 kg, the K400 is the most powerful Klaas trailer crane, with a hook height of more than 34 m. Equipped with a duar hydraulically telescopic fly jib, it represents considerable added value for everyday work in the urban sector, on tight building sites and in assembly mode. The first two elements of the fly jib can be retracted or extended by remote control, even in platform mode. This means that the trailer crane can be set up even where there is little room, thus opening up new application areas for working with and without a platform.

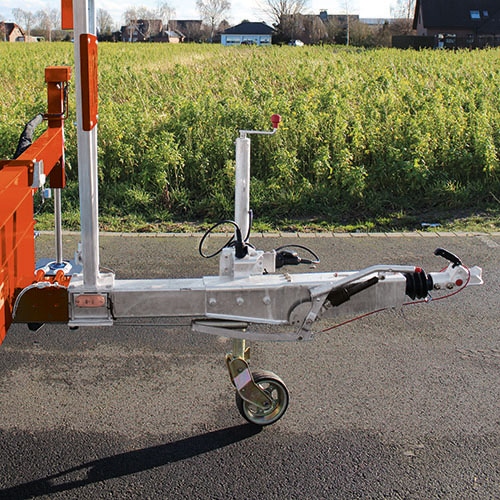

With the newly developed V2-support, the K400 has a support behaviour that is otherwise only known from large truck cranes. It ensures a quiet and safe stand even with high loads. The large lift of the outriggers enables a consistently large support surface even on uneven terrain and thus high performance values.