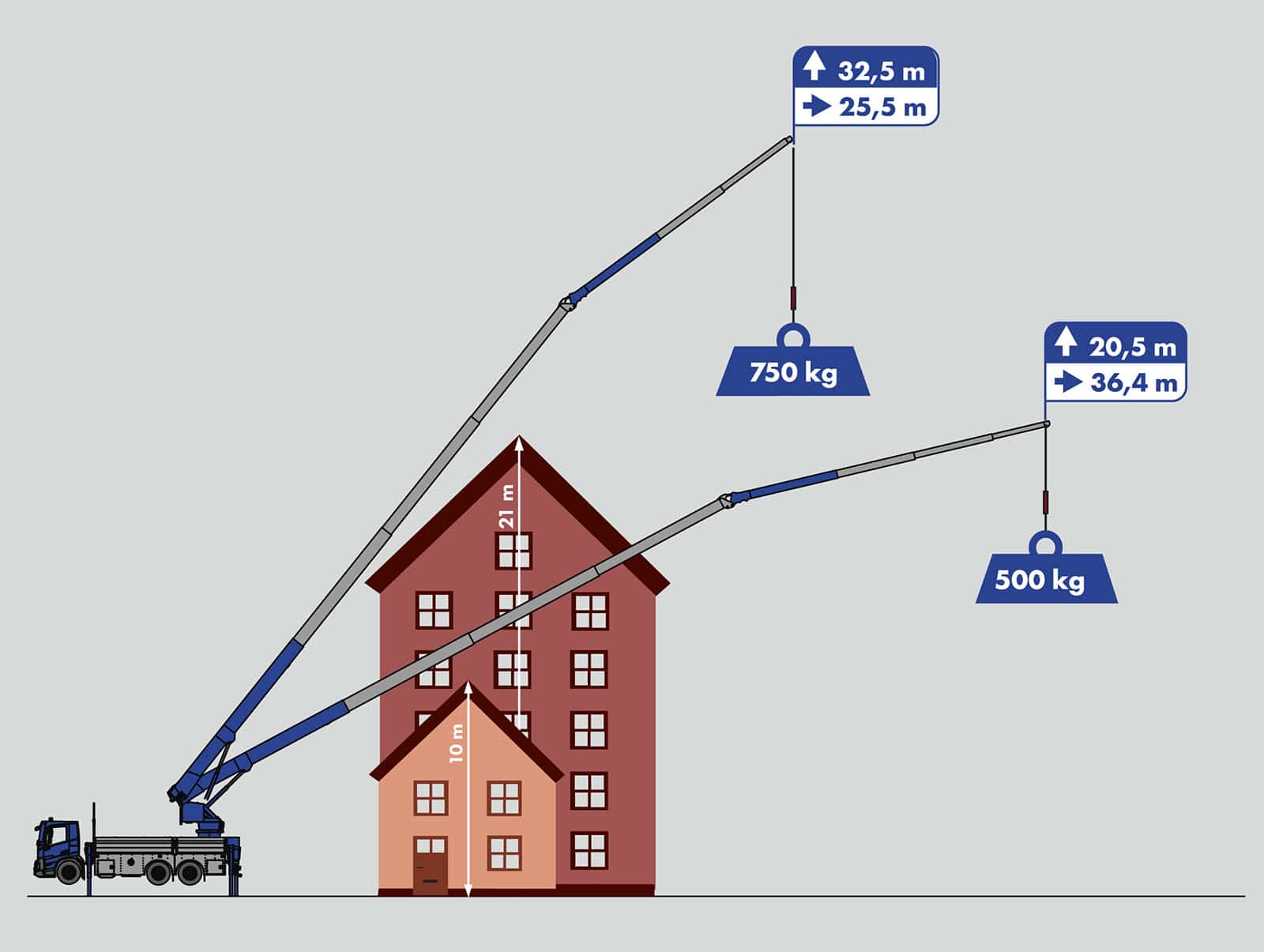

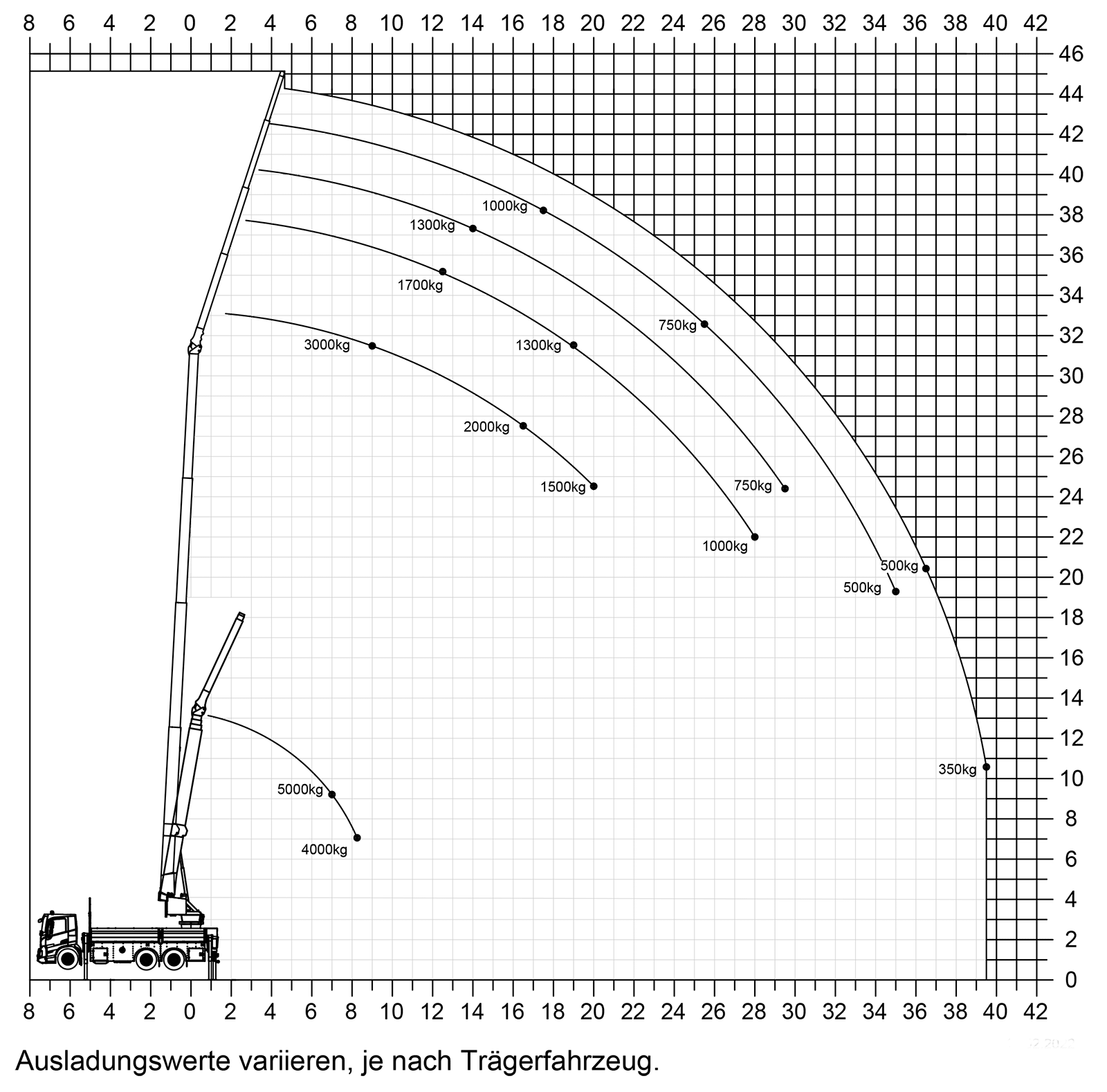

The K950 LHX combines a professional and large loading area with the enormous range of our powerful K950. And is therefore an ideal combination machine for building materials logistics specialists as well as for many trades around roofs and facades.

The maximum payload of the all-rounder is almost six tonnes – a value that is unique on the market for a 26-tonne truck on three axles in combination with its crane performance. The newly designed superstructure creates space for eight Euro pallets despite the compact chassis. Since its swing-through radius lies within the mirror contour, the city truck crane can also be used where space is limited.

Loading

Loading

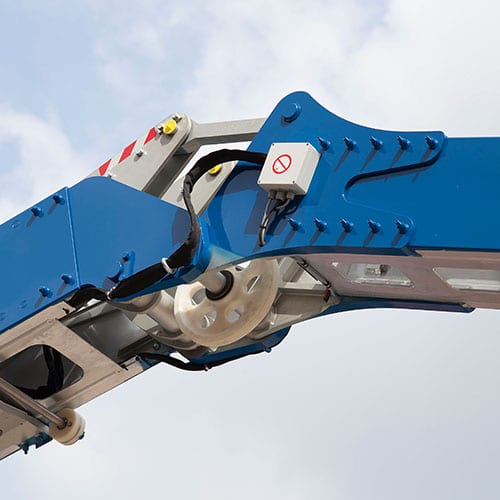

Compact superstructure

Compact superstructure

Full panelling

Full panelling