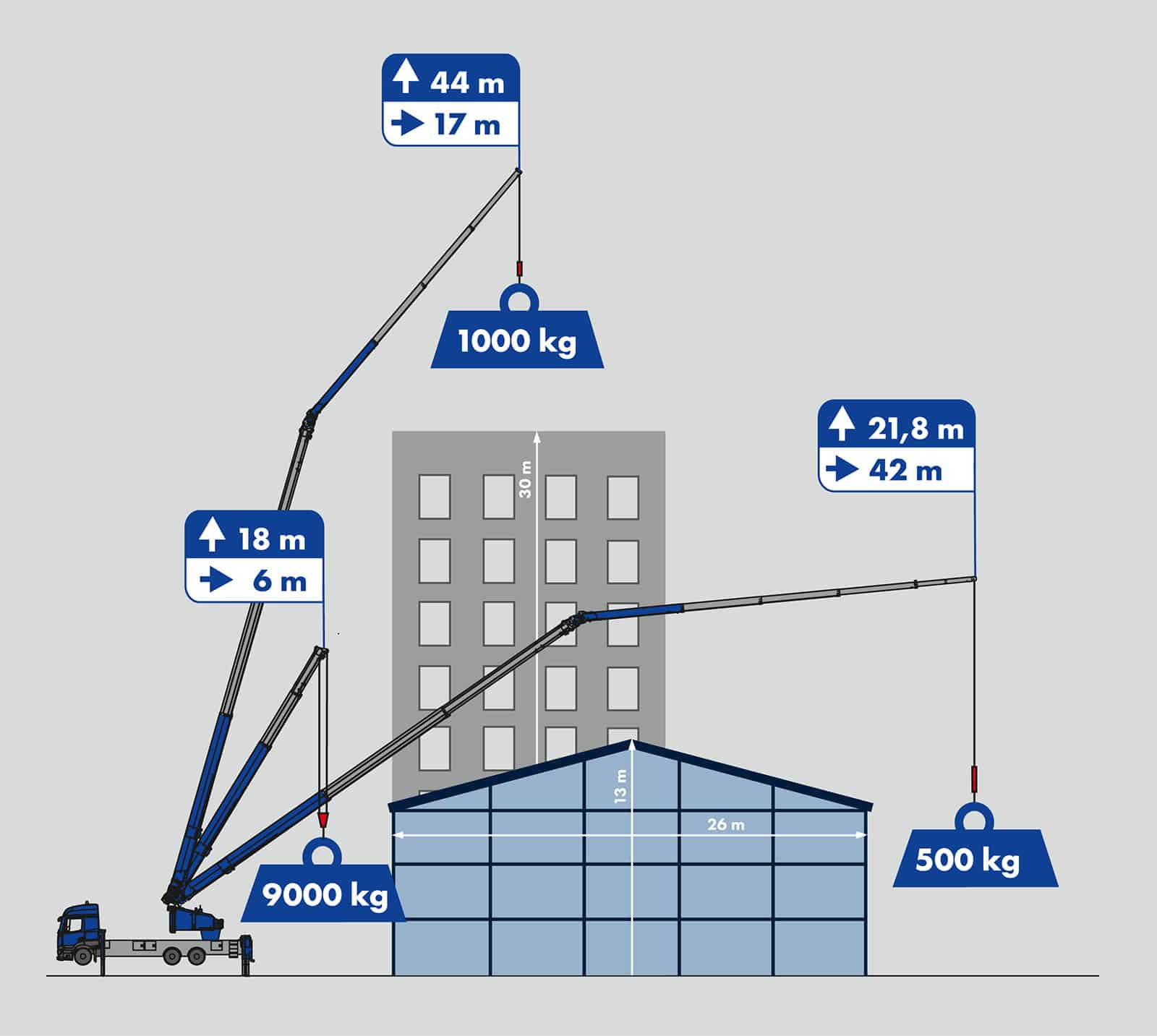

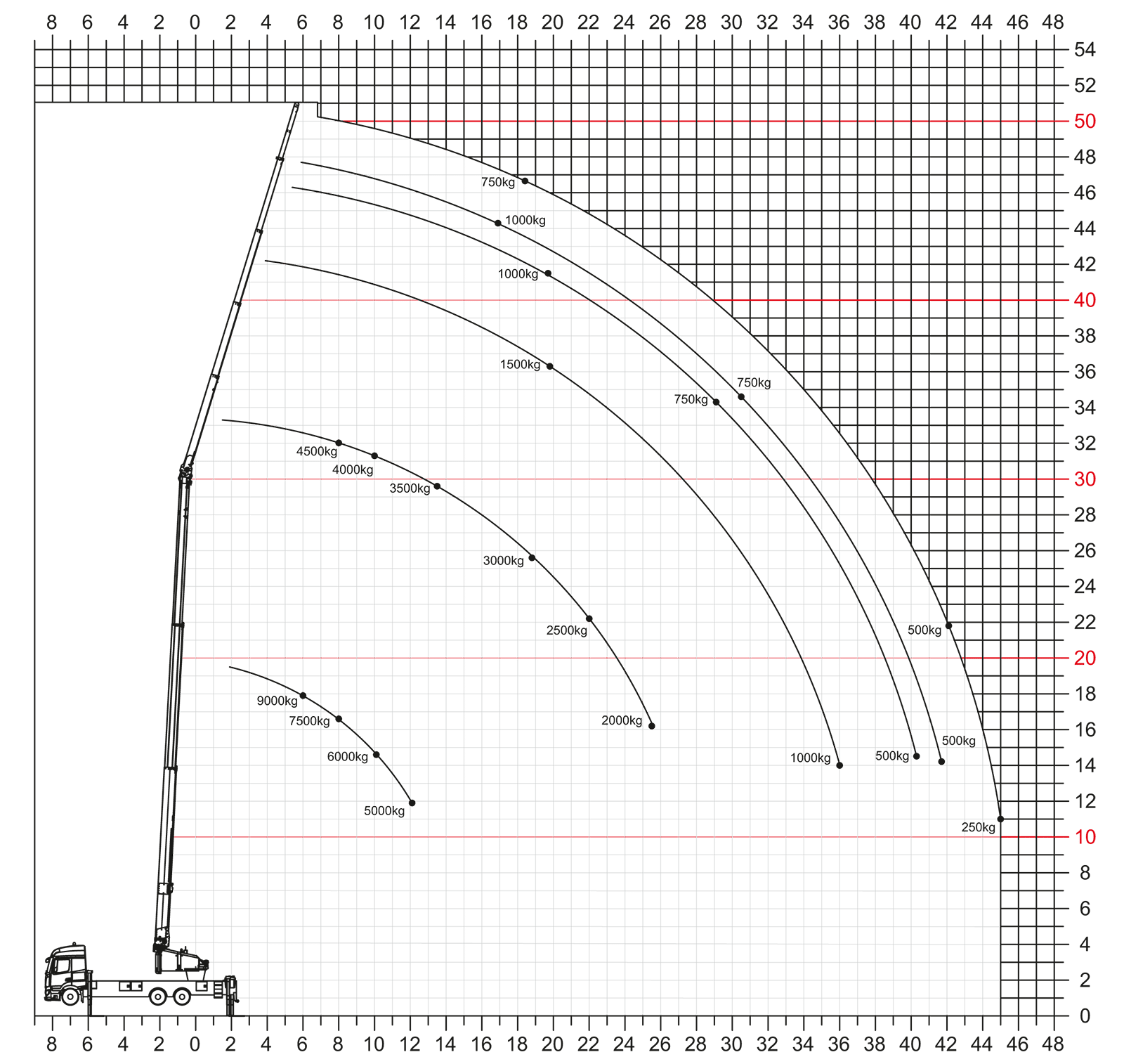

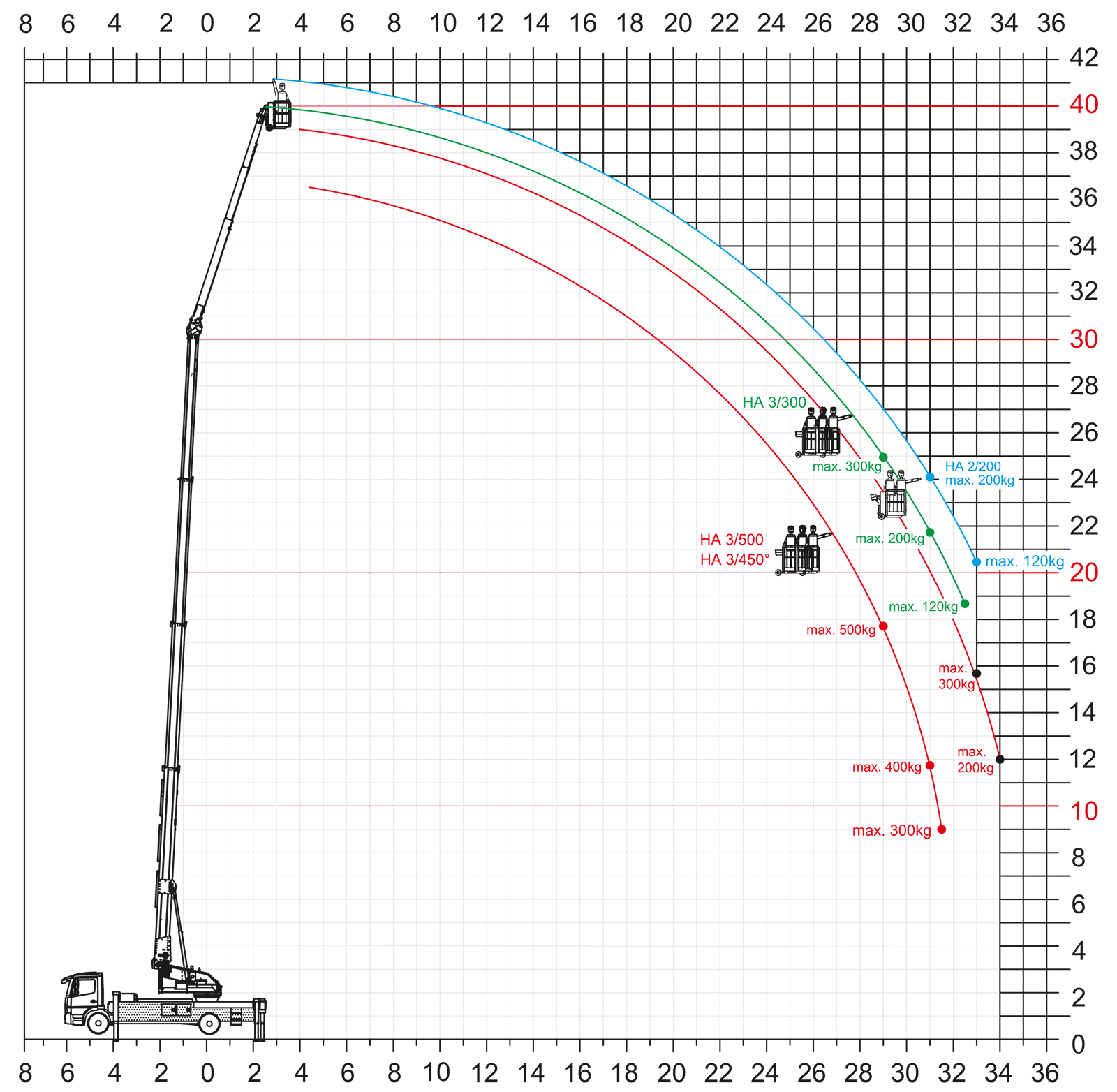

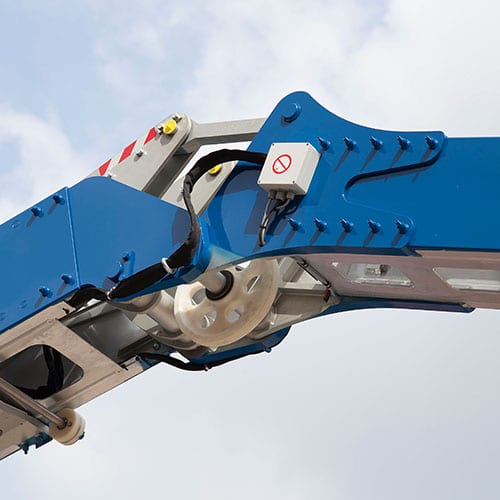

The new K2350 with a hook height of 50 m combines the enormous power of the K2300 with the innovative, triple hydraulically telescopic folding jib of the K2500.

Thanks to its solid aluminium rails and a particularly strong folding jib, this powerhouse can transport materials weighing up to 2,000 kg an impressive 26 m. Even with a hook load of three tonnes, it still achieves a lateral reach of 19 m. In single-rope operation, the powerful hoist can lift loads of up to 4,500 kg.

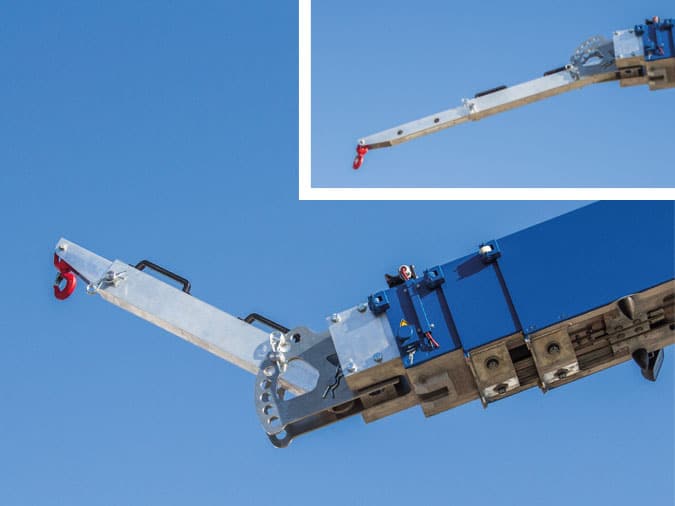

On request, the K2350 is available with a newly developed two-strand operation. This allows it to effortlessly lift up to 9 tonnes to a height of 18 m. Particularly practical: the change from single to double strand operation is automatic, tool-free and simply at the touch of a button on the remote control. As the second crane hook is already integrated into the mast, no additional assembly is required.

Solid support cylinders, double telescopic horizontal support beams and a maximum support width of only 7.34 m make the K2350 the perfect partner even in narrow city centres.

Full panelling

Full panelling

Two-string operation

Two-string operation