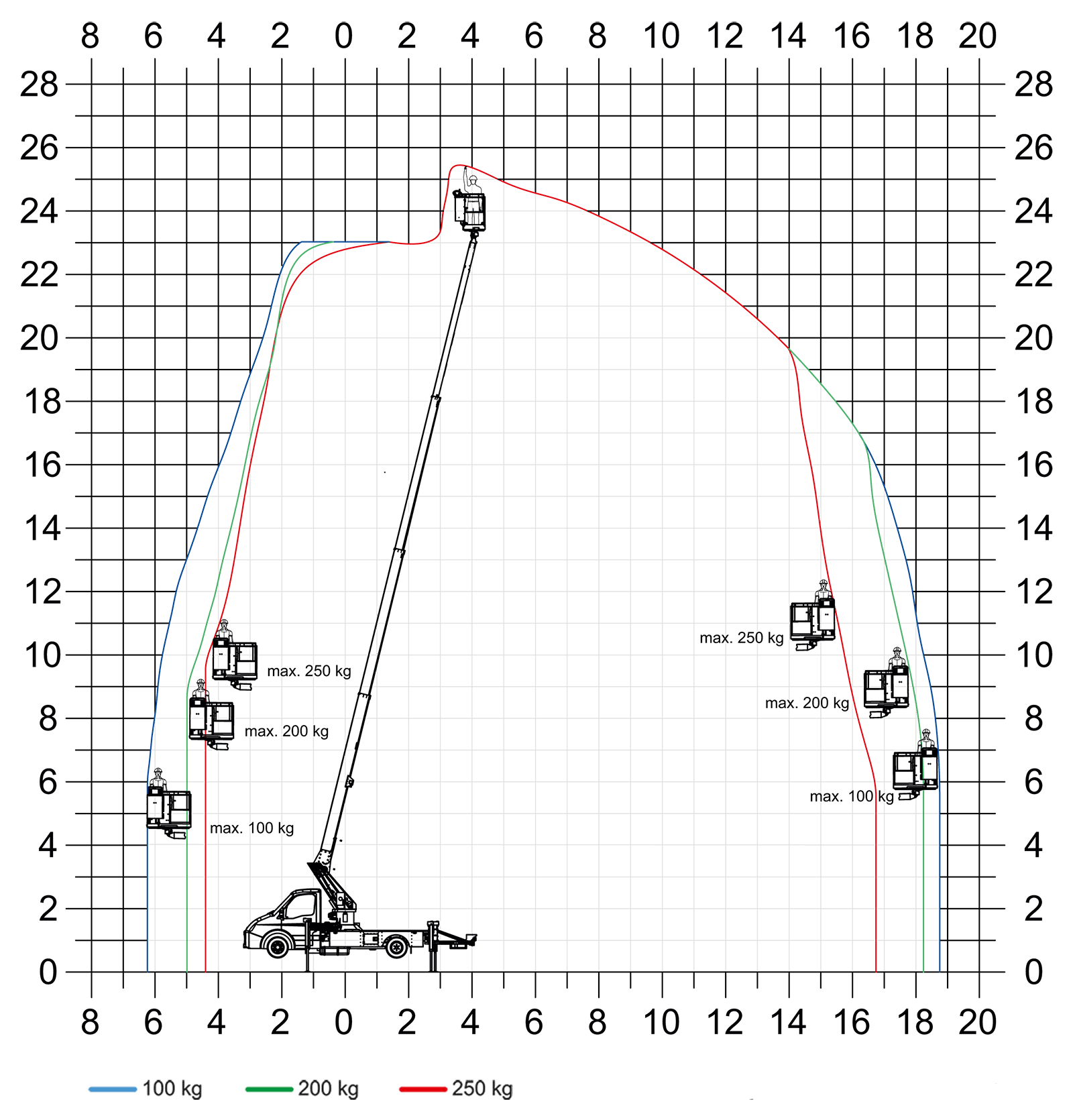

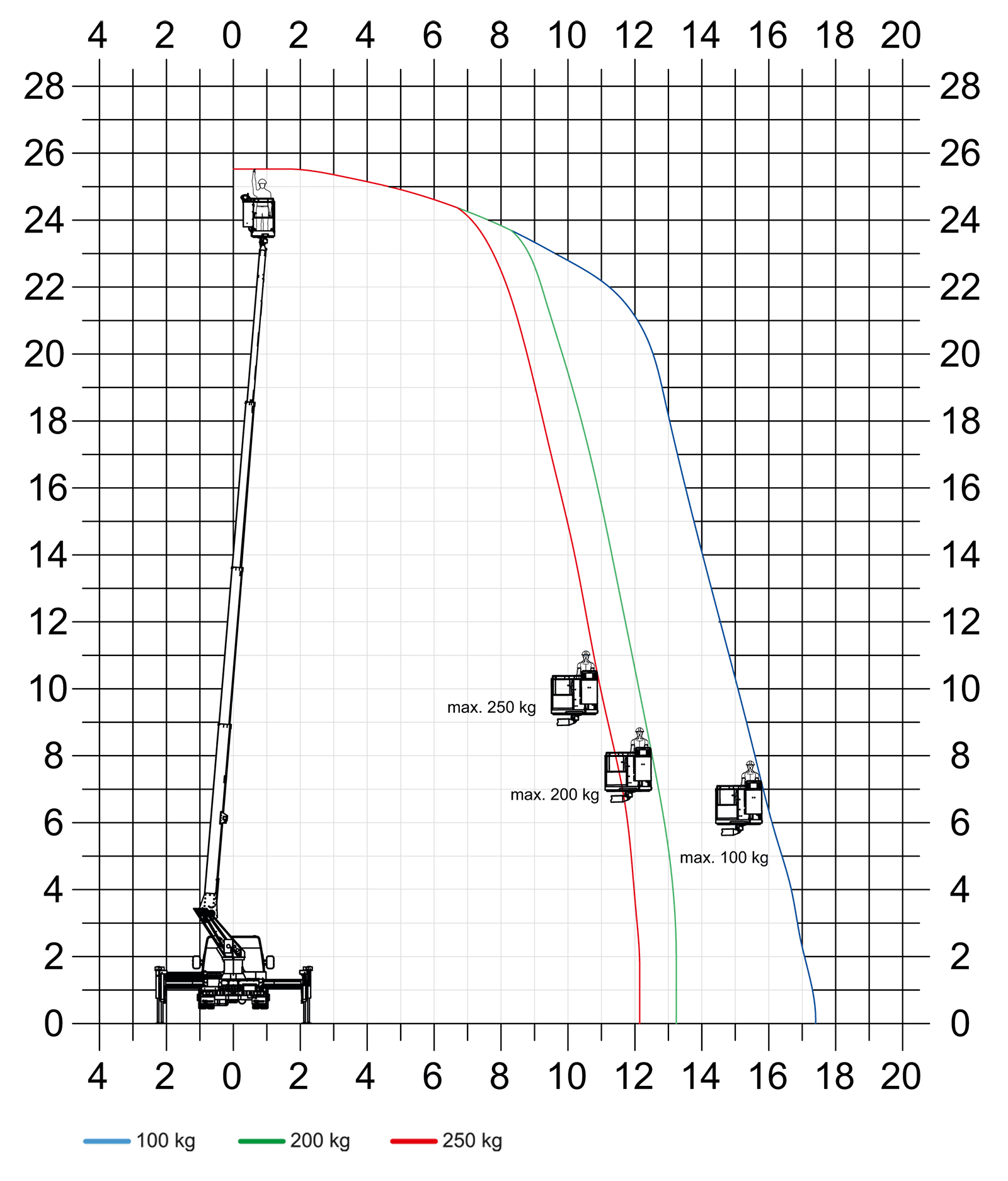

In addition to its enormous reach, the Theo25 V impresses with its ease of operation and simple handling. The 3.5 tonne platform is quickly and conveniently assembled and dismantled via the control panel. The low-maintenance rope technology enables telescoping under load, so that even hard-to-reach work areas can be reached without any problems. With a working height of 25 m and a reach of over 19 m, the Theo25 V is extremely versatile and facilitates work on roofs and façades as well as the installation of glass panes or the construction of industrial halls. It is the ideal helper for cities and municipalities when it comes to tree pruning, building cleaning or repair work.