Array

(

[noseries] => Array

(

[Hook load (stand./opt.)] => Array

(

[4.5 /6.0 t] => Array

(

[0] => 1

)

[1.6 /3.0 t] => Array

(

[0] => 2

)

[2.0 /4.0 t] => Array

(

[0] => 3

)

[3.0 /5.0 t] => Array

(

[0] => 4

[1] => 5

[2] => 6

[3] => 7

)

[3.0 /6.0 t] => Array

(

[0] => 8

[1] => 9

)

[4.5 /9.0 t] => Array

(

[0] => 10

)

)

[Hook height] => Array

(

[58.0 m] => Array

(

[0] => 1

)

[34.5 m] => Array

(

[0] => 2

)

[37.5 m] => Array

(

[0] => 3

)

[36.9 m] => Array

(

[0] => 4

)

[38.4 m] => Array

(

[0] => 5

)

[43.5 m] => Array

(

[0] => 6

[1] => 7

)

[52.2 m] => Array

(

[0] => 8

)

[60.0 m] => Array

(

[0] => 9

)

[48.0 m] => Array

(

[0] => 10

)

)

[Range (250 kg)] => Array

(

[30.0 m] => Array

(

[0] => 2

)

[32.0 m] => Array

(

[0] => 3

)

[39.5 m] => Array

(

[0] => 6

)

[44.0 m] => Array

(

[0] => 8

)

[47.0 m] => Array

(

[0] => 9

)

)

[Range (350 kg)] => Array

(

[39.5 m] => Array

(

[0] => 7

)

)

[Range (500 kg)] => Array

(

[45.0 m] => Array

(

[0] => 1

[1] => 9

)

[18.0 m] => Array

(

[0] => 2

)

[23.0 m] => Array

(

[0] => 3

)

[31.0 m] => Array

(

[0] => 4

)

[29.0 m] => Array

(

[0] => 5

)

[37.5 m] => Array

(

[0] => 6

)

[39.5 m] => Array

(

[0] => 7

)

[40.0 m] => Array

(

[0] => 8

)

[42.5 m] => Array

(

[0] => 10

)

)

[Range (1,000 kg)] => Array

(

[34.0 m] => Array

(

[0] => 1

[1] => 10

)

[14.0 m] => Array

(

[0] => 2

)

[13.5 m] => Array

(

[0] => 3

)

[25.0 m] => Array

(

[0] => 4

[1] => 5

)

[28.0 m] => Array

(

[0] => 6

[1] => 7

)

[30.0 m] => Array

(

[0] => 8

)

[35.0 m] => Array

(

[0] => 9

)

)

[Range (2,000 kg)] => Array

(

[22.5 m] => Array

(

[0] => 1

)

[6.0 m] => Array

(

[0] => 3

)

[15.0 m] => Array

(

[0] => 4

[1] => 5

)

[16.5 m] => Array

(

[0] => 6

[1] => 7

)

[18.5 m] => Array

(

[0] => 8

)

[23.0 m] => Array

(

[0] => 9

)

[26.0 m] => Array

(

[0] => 10

)

)

[Range (2,500 kg)] => Array

(

[19.0 m] => Array

(

[0] => 1

)

[17.0 m] => Array

(

[0] => 9

)

)

[Range (3,000 kg)] => Array

(

[16.0 m] => Array

(

[0] => 1

)

[7.5 m] => Array

(

[0] => 4

)

[9.0 m] => Array

(

[0] => 6

[1] => 7

[2] => 9

)

[11.0 m] => Array

(

[0] => 8

)

[19.0 m] => Array

(

[0] => 10

)

)

[Range (4,000 kg)] => Array

(

[12.0 m] => Array

(

[0] => 10

)

)

[Range (4,500 kg)] => Array

(

[10.0 m] => Array

(

[0] => 10

)

)

)

)

Array

(

[producttitle] => Array

(

[1] => Array

(

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[link] => https://klaas.com/en/produkt/k2500/

[productimage_medium] => https://klaas.com/wp-content/uploads/K2500_Volvo_2024-300x215.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/K2500_Volvo_2024-1024x735.jpg

)

[2] => Array

(

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[link] => https://klaas.com/en/produkt/k700/

[productimage_medium] => https://klaas.com/wp-content/uploads/k700-man-300x189.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k700-man-1024x644.jpg

)

[3] => Array

(

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[link] => https://klaas.com/en/produkt/k750-2/

[productimage_medium] => https://klaas.com/wp-content/uploads/k760-300x185.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k760-1024x633.jpg

)

[4] => Array

(

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[link] => https://klaas.com/en/produkt/k850/

[productimage_medium] => https://klaas.com/wp-content/uploads/k850-man-300x182.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k850-man-1024x621.jpg

)

[5] => Array

(

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[link] => https://klaas.com/en/produkt/k900/

[productimage_medium] => https://klaas.com/wp-content/uploads/k900-daf-1-300x206.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k900-daf-1-1024x704.jpg

)

[6] => Array

(

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[link] => https://klaas.com/en/produkt/k950/

[productimage_medium] => https://klaas.com/wp-content/uploads/k950-man-1-300x203.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k950-man-1-1024x692.jpg

)

[7] => Array

(

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[link] => https://klaas.com/en/produkt/k950-lhx/

[productimage_medium] => https://klaas.com/wp-content/uploads/k950-lhx-300x201.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k950-lhx-1024x685.jpg

)

[8] => Array

(

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[link] => https://klaas.com/en/produkt/k1003/

[productimage_medium] => https://klaas.com/wp-content/uploads/k1003-volvo-1-300x190.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k1003-volvo-1-1024x647.jpg

)

[9] => Array

(

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[link] => https://klaas.com/en/produkt/k1100/

[productimage_medium] => https://klaas.com/wp-content/uploads/k1100-volvo-300x204.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k1100-volvo-1024x696.jpg

)

[10] => Array

(

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[link] => https://klaas.com/en/produkt/k2300/

[productimage_medium] => https://klaas.com/wp-content/uploads/k2300-300x179.jpg

[productimage_large] => https://klaas.com/wp-content/uploads/k2300-1024x610.jpg

)

)

[Hook load (stand./opt.)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 4.5 /6.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[2] => Array

(

[slug] => k700

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 1.6 /3.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 2.0 /4.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 3.0 /5.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[5] => Array

(

[slug] => k900

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 3.0 /5.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 3.0 /5.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 3.0 /5.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 3.0 /6.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 3.0 /6.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 4.5 /9.0 t

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Hook height] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 58.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[2] => Array

(

[slug] => k700

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 34.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 37.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 36.9 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[5] => Array

(

[slug] => k900

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 38.4 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 43.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 43.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 52.2 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 60.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 48.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[link] => Array

(

[1] => Array

(

[link] => https://klaas.com/en/produkt/k2500/

[term_name] => ≥ 26 t

[term_ID] => 595

)

[2] => Array

(

[link] => https://klaas.com/en/produkt/k700/

[term_name] => ≥ 7.5 t

[term_ID] => 338

)

[3] => Array

(

[link] => https://klaas.com/en/produkt/k750-2/

[term_name] => ≥ 7.5 t

[term_ID] => 338

)

[4] => Array

(

[link] => https://klaas.com/en/produkt/k850/

[term_name] => ≥ 13.49 t

[term_ID] => 347

)

[5] => Array

(

[link] => https://klaas.com/en/produkt/k900/

[term_name] => ≥ 16 t

[term_ID] => 416

)

[6] => Array

(

[link] => https://klaas.com/en/produkt/k950/

[term_name] => ≥ 16 t

[term_ID] => 416

)

[7] => Array

(

[link] => https://klaas.com/en/produkt/k950-lhx/

[term_name] => ≥ 16 t

[term_ID] => 416

)

[8] => Array

(

[link] => https://klaas.com/en/produkt/k1003/

[term_name] => ≥ 22 t

[term_ID] => 417

)

[9] => Array

(

[link] => https://klaas.com/en/produkt/k1100/

[term_name] => ≥ 26 t

[term_ID] => 487

)

[10] => Array

(

[link] => https://klaas.com/en/produkt/k2300/

[term_name] => ≥ 26 t

[term_ID] => 487

)

)

[Range (250 kg)] => Array

(

[2] => Array

(

[slug] => k700

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 30.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 32.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 39.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 44.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 47.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (350 kg)] => Array

(

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 39.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (500 kg)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 45.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[2] => Array

(

[slug] => k700

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 18.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 23.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 31.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[5] => Array

(

[slug] => k900

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 29.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 37.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 39.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 40.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 45.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 42.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (1,000 kg)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 34.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[2] => Array

(

[slug] => k700

[name] => K700

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 14.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 13.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 25.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[5] => Array

(

[slug] => k900

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 25.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 28.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 28.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 30.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 35.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 34.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (2,000 kg)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 22.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[3] => Array

(

[slug] => k750-2

[name] => K760

[term_name] => ≥ 7.5 t

[term_ID] => 338

[term_count] => 0

[data] => 6.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 15.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[5] => Array

(

[slug] => k900

[name] => K900

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 15.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 16.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 16.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 18.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 23.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 26.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (2,500 kg)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 19.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 17.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (3,000 kg)] => Array

(

[1] => Array

(

[slug] => k2500

[name] => K2500

[term_name] => ≥ 26 t

[term_ID] => 595

[term_count] => 0

[data] => 16.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[4] => Array

(

[slug] => k850

[name] => K850

[term_name] => ≥ 13.49 t

[term_ID] => 347

[term_count] => 0

[data] => 7.5 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[6] => Array

(

[slug] => k950

[name] => K950

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 9.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[7] => Array

(

[slug] => k950-lhx

[name] => K950 LHX

[term_name] => ≥ 16 t

[term_ID] => 416

[term_count] => 0

[data] => 9.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[8] => Array

(

[slug] => k1003

[name] => K1003

[term_name] => ≥ 22 t

[term_ID] => 417

[term_count] => 0

[data] => 11.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[9] => Array

(

[slug] => k1100

[name] => K1100

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 9.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 19.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (4,000 kg)] => Array

(

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 12.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

[Range (4,500 kg)] => Array

(

[10] => Array

(

[slug] => k2300

[name] => K2300

[term_name] => ≥ 26 t

[term_ID] => 487

[term_count] => 0

[data] => 10.0 m

[series_slug] => noseries

[series_name] => noseries

[series_count] => 0

)

)

)

| ≥ 26 t | ≥ 7.5 t | ≥ 13.49 t | ≥ 16 t | ≥ 22 t | ≥ 26 t | |||||||||||||||||

K2500 K2500 |  K700 K700 |  K760 K760 |  K850 K850 |  K900 K900 |  K950 K950 |  K950 LHX K950 LHX |  K1003 K1003 |  K1100 K1100 |  K2300 K2300 | |||||||||||||

| Performance values | ||||||||||||||||||||||

| Hook load (stand./opt.) | 4.5 /6.0 t | 1.6 /3.0 t | 2.0 /4.0 t | 3.0 /5.0 t | 3.0 /5.0 t | 3.0 /5.0 t | 3.0 /5.0 t | 3.0 /6.0 t | 3.0 /6.0 t | 4.5 /9.0 t | ||||||||||||

| Hook height | 58.0 m | 34.5 m | 37.5 m | 36.9 m | 38.4 m | 43.5 m | 43.5 m | 52.2 m | 60.0 m | 48.0 m | ||||||||||||

| Range (250 kg) | – | 30.0 m | 32.0 m | – | – | 39.5 m | – | 44.0 m | 47.0 m | – | ||||||||||||

| Range (350 kg) | – | – | – | – | – | – | 39.5 m | – | – | – | ||||||||||||

| Range (500 kg) | 45.0 m | 18.0 m | 23.0 m | 31.0 m | 29.0 m | 37.5 m | 39.5 m | 40.0 m | 45.0 m | 42.5 m | ||||||||||||

| Range (1,000 kg) | 34.0 m | 14.0 m | 13.5 m | 25.0 m | 25.0 m | 28.0 m | 28.0 m | 30.0 m | 35.0 m | 34.0 m | ||||||||||||

| Range (2,000 kg) | 22.5 m | – | 6.0 m | 15.0 m | 15.0 m | 16.5 m | 16.5 m | 18.5 m | 23.0 m | 26.0 m | ||||||||||||

| Range (2,500 kg) | 19.0 m | – | – | – | – | – | – | – | 17.0 m | – | ||||||||||||

| Range (3,000 kg) | 16.0 m | – | – | 7.5 m | – | 9.0 m | 9.0 m | 11.0 m | 9.0 m | 19.0 m | ||||||||||||

| Range (4,000 kg) | – | – | – | – | – | – | – | – | – | 12.0 m | ||||||||||||

| Range (4,500 kg) | – | – | – | – | – | – | – | – | – | 10.0 m | ||||||||||||

| Details | Details | Details | Details | Details | Details | Details | Details | Details | Details | |||||||||||||

More than just height

Klaas mobile cranes have an unmistakable appearance thanks to their eye-catching boom system and full panelling with lockable storage compartments. Not only do they reach extreme heights but also excellent reach values even under high loads. Well thought out down to the last detail, they are always based on the needs of their users, allowing them to work conveniently and efficiently. Thanks to their enormous ranges, it is easy to transport materials even to the far side of the roof on a large building without repositioning the crane.

The Klaas boom system

The most striking trademark of a Klaas crane is its boom. This consists of high-strength aluminium profiles made from a special alloy and is produced in the stir welding process. It thus provides a strength as if milled from solid metal, a long service life and low maintenance costs. Its low net weight ensures outstanding reach

Another feature of our aluminium cranes is the extremely strong fly jib. When extended, it significantly increases the maximum hook height and enables a high lateral outreach. This means that even rear roof areas can be supplied with material if scaffolding or eaves prevent the main mast from being extended far. Almost all Klaas truck cranes and our largest trailer crane are equipped with a hydraulically telescopic fly jib that can be extended and retracted at the push of a button and virtually in mid-air.

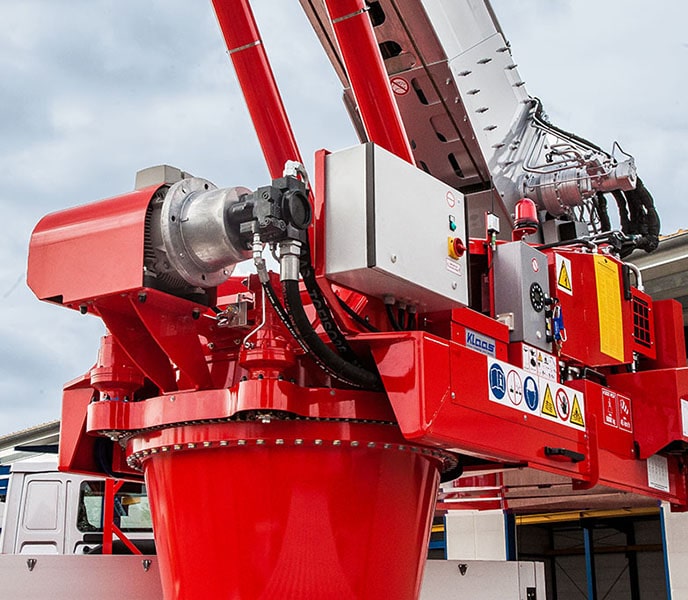

The patented Klaas winch technology enables quick and secure telescoping of mast and fly jip. And this, of course, also under load both in crane and platform operation. Four telescopic ropes are assembled on a single drum, whilst the track system is fixed into the cable technology. As the cables are guided and electrically monitored, slack ropes and skipping are prevented. An integrated electronic length measurement constantly records the current extension length of the mast and uses the data to calculate the maximum possible load capacity.

The Klaas support system

Pressing a button on the remote control starts the setting up of the crane and the automatic self-levelling. This ensures that all the outriggers have the same pressure and that the appliance is perfectly sturdy. Furthermore, the L-shape of the outriggers guarantees the best possible stability. Thanks to the fully hydraulic support system, it is possible to move each single support infinitely and accurately into position. Their long, vertical cylinders save them from being laboriously propped up on uneven terrain. As the outrigger widths can also be infinitely adjusted, even scaffolding, hedges or narrow alleys do not create an obstacle.

The ASC control system permanently monitors the stability of the appliance in crane and lifting platform mode and shows this via the remote control. At the same time it also takes changing wind or ground conditions into account. All crane functions are only activated if all four outriggers have an evenly high pressure, and if the support pressure is insufficient, a safety shutdown is automatically performed.

The Klaas crane control system

Klaas cranes are operated by a combination of a Sauer-Danfoss control block, a Wiedemann safety PLC and an intelligent remote control. The complex control system meets the requirements of EN 280 and EN 13000 and is programmed and coordinated according to Klaas specifications. A modern CAN bus control block with a soft start/stop function enables particularly delicate and precise work and prevents the boom from swinging dangerously. With the aid of a memory function, two target points can be learned within which the crane moves automatically and in safe hold-to-run operation. This makes it possible to approach hard-to-view areas with pinpoint accuracy and to unload quickly at positions that need to be approached repeatedly.

All important information can be read at a glance on the remote control display. It is operated via standard batteries or via cable - a key plus point should the wireless network be interrupted. Every Klaas crane can be equipped with a second radio remote control. This means that a second employee can take over the crane control and finish the job if positions are difficult to see.

The Klaas drive concept

The K950, K1003 and K1100 are equipped with two drives as standard. In addition to a powerful diesel engine, a 400-volt electric motor is installed, so that the crane operator can choose the type of drive depending on the construction site and operating conditions. The diesel engine is optimally adjusted to crane operation in terms of power, performance and consumption and can therefore be operated economically. Since it operates separately and independently, the truck engine is protected and its value is significantly maintained due to shorter operating times. The electric motor is operated via a 32-amp power supply. An automatic phase inverter guarantees the correct direction of rotation of the motor, eliminating the need to turn the phase manually and allowing the crane to be used immediately. The electric motor allows a comfortable and silent working without polluting exhaust gases.

All other mobile cranes are operated by a separate diesel engine as standard, the hybrid package can be ordered as an option. For the K700 and K750, the 400-volt electric motor is supplied separately. It can be mounted and dismounted in a few simple steps to ensure that the crane does not exceed the permissible gross weight for road transport.